What are the Differences Between Hydraulic and Mechanical Excavator Grapples?

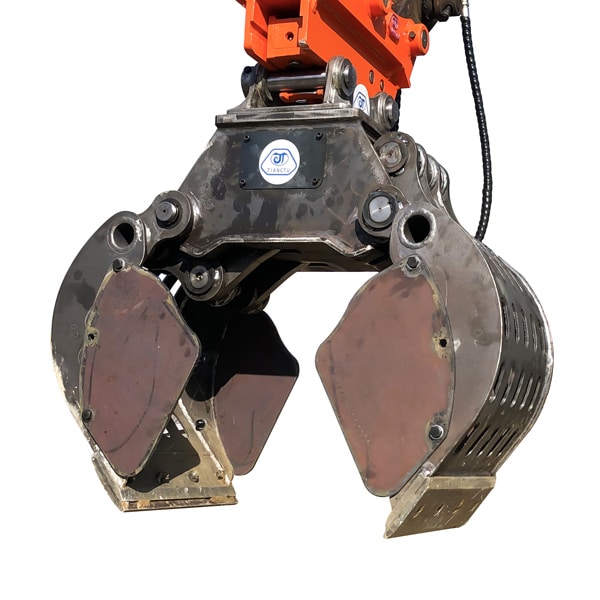

Excavator rotating grapples are attachments that are commonly used in demolition, construction, and mining projects. They are designed to facilitate material handling and improve work efficiency. Excavator grapples come in different types, each with unique operating principles, advantages, and disadvantages. Choosing the right grapple for your project can be challenging, especially if you are not familiar with the different types available.

In this article, we will provide an overview of hydraulic and mechanical excavator rotating grapples, and factors to consider when choosing the right type for your project.

JIANGTU Excavator Grapple is a kind of excavator attachment that is mainly used for steel scraps, wastes handling, loading, and unloading. As one of the leading excavator grapple manufacturers in China, JIANGTU has a full range of hydraulic grapples for excavators from 3-40 tons. They are suitable for all kinds of brands and models of excavators.

View our Product

Importance of Choosing the Right Grapple Type

Choosing the right grapple for your project is crucial to ensure work efficiency, safety, and cost-effectiveness. A mismatched grapple can lead to project delays, increased maintenance costs, and even accidents. It is essential to consider project requirements, excavator compatibility, budget constraints, and maintenance considerations when selecting a grapple type.

Hydraulic Excavator Rotating Grapples

Operating Principles

Hydraulic excavator rotating grapples operate using hydraulic power from the excavator’s hydraulic system. They are designed to open and close using hydraulic cylinders, allowing them to grip and release objects. Hydraulic grapples can be further classified into two types, namely, single-acting and double-acting grapples.

Advantages

Hydraulic excavator grapples offer several advantages, including:

- High gripping force

- Ability to handle various types of materials

- Faster operating speed

- Precise control over the grip force

- Ability to rotate 360 degrees

- Easy to install and remove

Disadvantages

Hydraulic excavator grapples also have some disadvantages, including:

- High initial cost

- Requires regular maintenance

- Can be affected by temperature changes

- Requires a compatible hydraulic system in the excavator

Ideal Applications

Hydraulic excavator grapples are ideal for handling large and heavy materials, such as rocks, logs, and debris. They are also suitable for demolition and construction projects that require precise handling and control.

Grab For Excavator

| Wood/Log Grapple | Light Wood Grapple | Orange Peel Grapple | Demolition Grapple | Hydraulic Grab | Hydraulic Grapple | |

| Application | loading and unloading, handling rocks timber logs, electric poles, pipes and various strips, etc,building materials, stone and steel pipes, etc | loading and unloading, handling rocks, stone and steel pipes, building materials, etc | loading and unloading, handling timber logs, pipes, etc | used for demolition construction waste cleaning | loading and unloading rocks,construction waste, straw etc | loading and unloading, handling rocks, stone and steel pipes, building materials etc |

| Tine Number | 3+2/3+4 | 1+1 | 4Tine /5Tine | 1+1 | 3+2 | 3+2/3+4 |

| Materials | Q355B and wear plate with M+S motor USA-made solenoid valve Germany-made oil seals | Q355B and wear plate/M+S motor with brake valve; cylinder with USA safety | Imported M+S motor ; NM500 steel and all pins are heat-treated; Original German oil seals; | Q355B and wear plate imported M+S motor; Original German oil seals; | Q355B and wear plate with USA-made solenoid valve; Original Germany-made oil seals and joints | Q355B and wear plate with USA-made solenoid valve; Original Germany-made oil seals and joints |

| Excavator tons | 5-40 ton | 1.5-23 ton | 4-30 ton | 1.5-23 ton | 1.5-30ton | 1.5-30 ton |

| Hot sale area | Global | Global | Global | Europe | Australia | Asia |

Mechanical Excavator Rotating Grapples

Operating Principles

Mechanical excavator rotating grapples operate using a mechanical linkage system. They are designed to open and close using mechanical force, allowing them to grip and release objects. Mechanical grapples can be further classified into two types, namely, fixed and rotating grapples.

Advantages

Mechanical excavator grapples offer several advantages, including:

- Lower initial cost

- Less maintenance required

- Resistant to temperature changes

- Can be used with non-hydraulic excavators

Disadvantages

Mechanical excavator grapples also have some disadvantages, including:

- Lower gripping force compared to hydraulic grapples

- Cannot handle certain types of materials

- Limited operating speed

- Limited control over the grip force

- Cannot rotate 360 degrees

Ideal Applications

Mechanical excavator grapples are ideal for handling small to medium-sized materials, such as soil, sand, and gravel. They are also suitable for excavation and landscaping projects that require a lower gripping force.

Key Differences Summary

Hydraulic excavator grapples operate using hydraulic power, while mechanical grapples operate using a mechanical linkage system.

Hydraulic grapples offer higher gripping force, faster operating speed, and more precise control over the grip force, while mechanical grapples offer a lower initial cost and require less maintenance.

Hydraulic grapples are suitable for handling large and heavy materials, while mechanical grapples are suitable for handling small to medium-sized materials.

Factors to Consider When Choosing

Project Requirements

When choosing an excavator grapple, it is essential to consider the project requirements. The grapple should be able to handle the materials that will be encountered in the project, and it should be suitable for the working environment. For example, a hydraulic excavator grapple may be more suitable for a demolition project that requires the handling of large and heavy materials, while a mechanical excavator grapple may be more appropriate for a landscaping project that requires the handling of small to medium-sized materials.

Excavator Compatibility

The excavator grapple should be compatible with the excavator that will be used for the project. The size and weight of the grapple should be appropriate for the excavator, and the hydraulic or mechanical system should be compatible with the excavator’s system. Using a mismatched grapple can cause damage to the excavator and compromise safety.

Budget Constraints

Budget constraints are also a significant consideration when choosing an excavator grapple. Hydraulic excavator grapples are typically more expensive than mechanical grapples, and the cost can vary depending on the brand, size, and features of the grapple. It is important to consider the long-term costs, including maintenance and repair costs when making a purchasing decision.

Maintenance Considerations

Excavator grapples require regular maintenance to ensure optimal performance and prevent breakdowns. Hydraulic grapples require more maintenance than mechanical grapples due to their more complex system. It is important to consider the maintenance requirements and costs when choosing a grapple type.

Conclusion

Choosing the right excavator rotating grapple is crucial for project efficiency, safety, and cost-effectiveness. Hydraulic and mechanical grapples have unique operating principles, advantages, and disadvantages, making it essential to consider project requirements, excavator compatibility, budget constraints, and maintenance considerations when making a purchasing decision. It is important to choose a grapple type that is suitable for the project’s materials and working environment and to ensure compatibility with the excavator. Regular maintenance is also essential to ensure optimal performance and prevent breakdowns.