Tips for Pallet Truck Maintenance

Forklift tip over

Components of a forklift

Tips for Pallet Truck Maintenance

March 9, 2022

What parts do you need to prioritize during pallet truck maintenance?

- Wheels

- Batteries

- Forks

- Bearings

- Hydraulic System

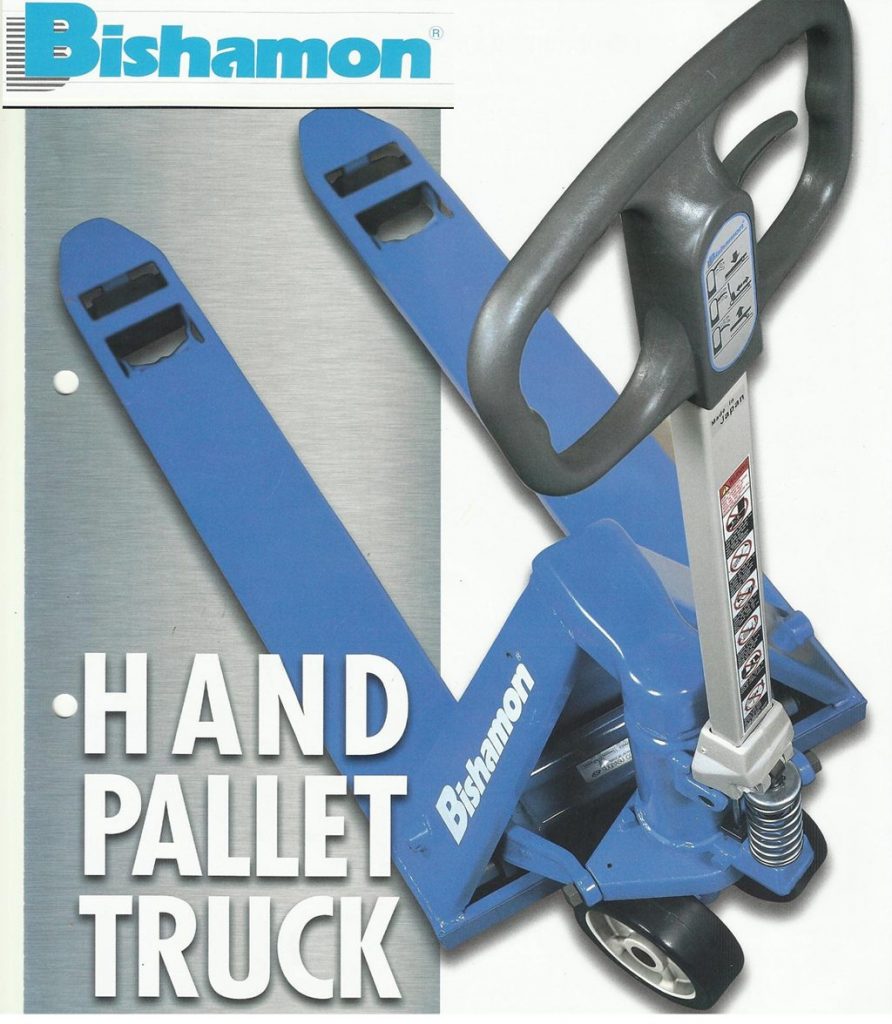

A hand pallet truck is designed to carry, lift, and transport pallets. This wheeled trolley has fork slots underneath that slides under a pallet and a pump handle that is used to raise or lower the load. It is a useful material handling equipment for stockrooms, warehouses, and facilities where pallets are mainly used. But just like other equipment on your site, they also require regular upkeep. Here are some tips for pallet truck maintenance. Keep on reading!

Wheels

The wheels on a hand pallet truck make it possible to transport pallets across a facility. These are typically made of nylon or polyurethane. Nylon is ideal for rough, wet, and cold floors, while polyurethane is made for retail floors. It’s important to choose the right one to reduce wear and tear.

But over time, these can become worn out — especially when they’re neglected. Different types of dirt can get stuck between the wheels, which can affect their function and lead to premature wearing. For example, the forks might not lower completely due to debris. But by keeping your workplace clean, the wheels can glide on smoothly and the accumulation of dirt can be prevented. It’s also a good practice to remove the contaminants before using the pallet truck.

Overloaded pallet trucks are also the cause of worn-out wheels. By carrying heavy loads, the wheels form a flat spot that can cause a vibration when rolling. This often occurs when you park the truck with heavy loads for a while.

Batteries

Batteries are essential for electric hand pallet trucks. These power the electric motor on the equipment. To prolong the lifespan of batteries, operators should know how to check the battery charge level, how to change batteries, and how to protect the component from the elements. These are key in keeping the machine working properly.

Most electric pallet trucks allow battery swapping, so you can charge one battery while using another one on the equipment. But the batteries must be safely removed, as damages can impact efficiency. It’s also worth it to invest in weather protection accessories if you plan to use the truck in cold environments, as batteries are less efficient when it’s cold.

Forks

The forks are exposed to heavy loads daily, so they’re more prone to wear and tear if neglected or not used correctly. For example, chipping and bending are often caused when the forks are not lowered properly before sliding underneath a pallet. The forks could also break over time if the load is not properly distributed. This can lead to accidents and property damage in your facility.

For this reason, the forks should be inspected daily. Look for areas with chipping, buckling, or bending and report the problem immediately. While paint chips are a normal occurrence, structural damages are a more serious problem, so it’s best to prevent this through proper use of the pallet truck.

Bearings

A well-oiled hand pallet truck is necessary to avoid malfunction. Although all bearings and axles are lubricated when you first bought your equipment, you will need to regularly lubricate them as it could lead to friction, rusting, and corrosion.

It’s a good practice to lubricate the pallet truck monthly or after each cleaning. This includes the wheels, axles, and other lubrication points. You should use the right type of lubricant, as something too thick can cause issues.

Part of an Excavator–Hydraulic System

Always inspect the hydraulic unit of the pallet truck for signs of leaks and spills. If this occurs, have the equipment inspected by a professional immediately.

Before operation, test the equipment by loading it. By doing this, you can spot malfunctions. For instance, if the jack can’t raise the load properly, there could be an air lock in the pump. You can fix this by switching the lever into release, then manually pumping the handle for 5 minutes. This will expel the air and allow the forks to function normally again. Another reason why the jack will fail to raise the load is because of low fluid level.

On the other hand, if the jack can’t lower the load, there could be bent frame parts. Replace these immediately to restore function to the pallet truck.

Key Takeaway

Pallet truck maintenance is key to prolonging the service life of your material handling equipment. From the wheels to the batteries, forks, bearings, and hydraulic system, you have to consistently look for signs of wear and tear, so you can prevent problems in the future. Regular maintenance of these components ensures that your equipment will reliable when you need it.

If you’re looking for hand pallet trucks, you can send us a message here at Multico! Aside from these, we are also a trusted supplier of forklifts, which is another material handling equipment that can carry, lift, and transport loads. If you require, we can also provide preventive maintenance services for your forklift and hand pallet trucks.