What Is The Most Common Excavator Bucket?

Excavator buckets are vital components in the realm of construction and excavation, serving as essential attachments for a variety of tasks. Among the various types available, the general-purpose excavator bucket stands out as the most common and versatile option. Its robust design and adaptable nature make it an indispensable tool on construction sites worldwide.

In this article, we will delve into the key features, advantages, limitations, and common applications of the general-purpose excavator bucket. By understanding its capabilities, contractors can make informed decisions on selecting the right attachment for their specific projects, ultimately enhancing efficiency and productivity in their construction and excavation endeavors.

Overview of Excavator Buckets

Excavator buckets come in a diverse array of types, each tailored to perform specific tasks and tackle various materials with precision. From digging and trenching to loading and material handling, there is a bucket for nearly every construction need. However, among the assortment of options available, the general-purpose excavator bucket stands as the most prevalent and versatile attachment. Its design is well-suited for efficiently digging, lifting, and loading, making it an indispensable tool in construction and excavation projects across the globe.

The general-purpose excavator bucket features a smooth, slightly curved shape, constructed with high-strength steel to endure the rigors of demanding job sites. Its cutting edge, side cutters, and teeth are skillfully designed to penetrate and scoop various materials, including soil, gravel, sand, and small rocks. Moreover, these buckets are available in an assortment of sizes and capacities, ensuring compatibility with different excavator models and accommodating various job requirements. The general-purpose excavator bucket’s adaptability and efficiency make it a go-to choice for contractors seeking a versatile and reliable attachment to tackle a wide range of tasks.

The General Purpose Excavator Bucket

The general-purpose excavator bucket, as its name suggests, is a true workhorse on construction and excavation sites. Its standard design and functionality make it suitable for a multitude of applications. The bucket’s smooth and slightly curved shape facilitates efficient digging and material scooping, allowing for quick and effective excavation tasks. The cutting edge and teeth enable the bucket to penetrate various materials with ease, providing excellent digging performance.

Made from high-strength steel, the general-purpose bucket is built to withstand the harsh conditions often encountered in construction and excavation projects. Its robust construction ensures durability and longevity, reducing the need for frequent replacements and maintenance. The design also helps in minimizing material carryback, promoting efficient loading and reducing spillage, thus optimizing productivity on the job site.

JIANGTU Excavator Bucket is the perfect choice for grading and leveling earthwork. Obliquely manipulate this excavator attachment to the precise angle required, so that you are more efficient in handling work, and do not have to constantly reposition your excavator.

Skeleton Bucket

Thumb Bucket

Tilt Bucket

Rock Bucket

Crusher Bucket

Clean-Up Buckets

Rotating Screening Bucket

Contractors value the general-purpose excavator bucket for its simplicity and reliability. Its straightforward design translates to ease of use, allowing operators to quickly adapt and familiarize themselves with the attachment. The bucket’s versatility and wide range of applications make it a cost-effective choice for various projects. Whether excavating, trenching, backfilling, or loading materials, the general-purpose bucket proves to be a valuable asset, streamlining tasks and contributing to the overall efficiency of construction and excavation operations.

Advantages of the General Purpose Excavator Bucket

The general-purpose excavator bucket offers a multitude of advantages that make it a preferred choice for many construction and excavation tasks. One of its key advantages is its versatility. Contractors can use this bucket for a wide range of applications, eliminating the need to switch attachments frequently during a project. From digging and trenching to loading and material handling, the general-purpose bucket excels in various job site requirements, simplifying the equipment setup and enhancing workflow efficiency.

Another significant advantage is the general-purpose bucket’s efficient digging and material handling capabilities. The smooth, slightly curved design and well-positioned teeth allow for effective penetration and excavation in different soil conditions. Its excellent scooping ability ensures optimal material collection and transfer, enhancing productivity during loading and stockpiling operations. Contractors can rely on the general-purpose bucket’s consistent performance to complete tasks quickly and effectively.

Furthermore, the general-purpose excavator bucket is a cost-effective solution for construction and excavation projects. Its widespread use and availability translate to competitive pricing, making it a budget-friendly choice for contractors and rental companies. Additionally, its simple and durable design requires minimal maintenance, reducing downtime and overall operating costs. Contractors appreciate the bucket’s reliability and cost-effectiveness, knowing they can rely on it to deliver consistent results on various job sites.

Common Applications of the General Purpose Excavator Bucket

The general-purpose excavator bucket finds extensive use in a wide range of construction and excavation applications. One of its primary roles is in digging and excavation tasks, where it can efficiently remove various types of soil and materials. From breaking ground for foundation work to creating trenches for utilities installation, the general-purpose bucket’s digging capabilities are invaluable.

Additionally, the bucket’s ability to load and stockpile materials makes it an essential attachment on job sites. Contractors can use it to transport and place soil, gravel, sand, and other materials, streamlining material handling operations. Whether loading trucks for transport or stockpiling materials for future use, the general-purpose bucket ensures efficient and precise material placement.

Grading and leveling tasks are also well-suited to the general-purpose excavator bucket. Its smooth and slightly curved design allows for precise finishing and grading of surfaces. Contractors can use the bucket to achieve the desired contour and smoothness in landscaping and road construction projects, ensuring a professional and polished finish.

The versatility of the general-purpose bucket extends beyond traditional construction and excavation projects. It is also useful in agriculture, where it can be used for tasks such as clearing land, digging irrigation ditches, and handling farm materials. Its adaptability makes it a valuable asset in various industries, making it a go-to attachment for a wide range of applications.

In conclusion, the general-purpose excavator bucket proves its worth in diverse construction, excavation, and material handling tasks. Its ability to efficiently dig, load, and grade materials, combined with its cost-effectiveness and reliability, make it a staple on job sites worldwide. Contractors can rely on this versatile attachment to deliver consistent performance and contribute to the successful completion of various projects. Whether in construction, agriculture, or other industries, the general-purpose bucket stands as a reliable workhorse, enhancing productivity and efficiency in a myriad of applications.

#kt-layout-id_aede2a-b0 > .kt-row-column-wrap{align-content:start;}:where(#kt-layout-id_aede2a-b0 > .kt-row-column-wrap) > .wp-block-kadence-column{justify-content:start;}#kt-layout-id_aede2a-b0 > .kt-row-column-wrap{column-gap:var(–global-kb-gap-md, 2rem);row-gap:var(–global-kb-gap-md, 2rem);padding-top:var( –global-kb-row-default-top, 25px );padding-bottom:var( –global-kb-row-default-bottom, 25px );padding-left:20px;padding-right:20px;grid-template-columns:minmax(0, 1fr);}#kt-layout-id_aede2a-b0{border-top-left-radius:8px;border-top-right-radius:8px;border-bottom-right-radius:8px;border-bottom-left-radius:8px;overflow:hidden;isolation:isolate;border-color:var(–global-palette3, #1A202C);border-top-width:1.5px;border-right-width:1.5px;border-bottom-width:1.5px;border-left-width:1.5px;}#kt-layout-id_aede2a-b0 > .kt-row-layout-overlay{opacity:0.46;}#kt-layout-id_aede2a-b0 ,#kt-layout-id_aede2a-b0 h1,#kt-layout-id_aede2a-b0 h2,#kt-layout-id_aede2a-b0 h3,#kt-layout-id_aede2a-b0 h4,#kt-layout-id_aede2a-b0 h5,#kt-layout-id_aede2a-b0 h6{color:var(–global-palette3, #1A202C);}#kt-layout-id_aede2a-b0 a{color:var(–global-palette3, #1A202C);}#kt-layout-id_aede2a-b0 a:hover{color:#e76106;}@media all and (max-width: 1024px){#kt-layout-id_aede2a-b0 > .kt-row-column-wrap{grid-template-columns:minmax(0, 1fr);}}@media all and (max-width: 767px){#kt-layout-id_aede2a-b0 > .kt-row-column-wrap{grid-template-columns:minmax(0, 1fr);}}

Read More: The working principle of excavator attachments

- The Working Principle of Hydraulic Breaker

- The Working Principle of Excavator Ripper

- The Working Principle of Hydraulic Auger

- Hydraulic Grapple Working Principle

- The Working Principle of Quick Hitch Coupler

- The Working Principle of Skid Steer Tree Spade

- The Working Principle of Skid Steer Snow Throwers

.kadence-column_6bb113-5b > .kt-inside-inner-col{border-top-width:0px;border-right-width:0px;border-bottom-width:0px;border-left-width:0px;}.kadence-column_6bb113-5b > .kt-inside-inner-col,.kadence-column_6bb113-5b > .kt-inside-inner-col:before{border-top-left-radius:0px;border-top-right-radius:0px;border-bottom-right-radius:0px;border-bottom-left-radius:0px;}.kadence-column_6bb113-5b > .kt-inside-inner-col{column-gap:var(–global-kb-gap-sm, 1rem);}.kadence-column_6bb113-5b > .kt-inside-inner-col{flex-direction:column;}.kadence-column_6bb113-5b > .kt-inside-inner-col > .aligncenter{width:100%;}.kadence-column_6bb113-5b > .kt-inside-inner-col:before{opacity:0.3;}.kadence-column_6bb113-5b{position:relative;}@media all and (max-width: 1024px){.kadence-column_6bb113-5b > .kt-inside-inner-col{flex-direction:column;}}@media all and (max-width: 767px){.kadence-column_6bb113-5b > .kt-inside-inner-col{flex-direction:column;}}

Contact For Our Expert

Find out which attachment & Excavator works best for you!

.kadence-form-_b71a8f-dd .kb-form .kadence-blocks-form-field .kb-text-style-field, .kadence-form-_b71a8f-dd .kb-form .kadence-blocks-form-field .kb-select-style-field{color:var(–global-palette9, #ffffff);background:var(–global-palette3, #1A202C);}.kadence-form-_b71a8f-dd .kb-form .kadence-blocks-form-field .kb-text-style-field:focus, .kadence-form-_b71a8f-dd .kb-form .kadence-blocks-form-field .kb-select-style-field:focus{color:var(–global-palette9, #ffffff);}.kadence-form-_b71a8f-dd .kb-form .kadence-blocks-form-field .kb-forms-submit{color:var(–global-palette3, #1A202C);background:rgba(50, 150, 255, 0.92);border-color:var(–global-palette3, #1A202C);box-shadow:2px 2px 3px 0px rgba(0, 0, 0, 0.2);}.kadence-form-_b71a8f-dd .kb-form .kadence-blocks-form-field .kb-forms-submit:hover, .kadence-form-_b71a8f-dd .kb-form .kadence-blocks-form-field .kb-forms-submit:focus {color:#156fce;border-color:#1575d5;box-shadow:2px 2px 3px 0px rgba(0, 0, 0, 0.4);background:var(–global-palette3, #1A202C);}

.kadence-form-_b71a8f-dd .kadence-blocks-form-field.kb-submit-field { display: none; }

Related Articles

How to Select Breaker Chisel Tools for Hydraulic Hammer

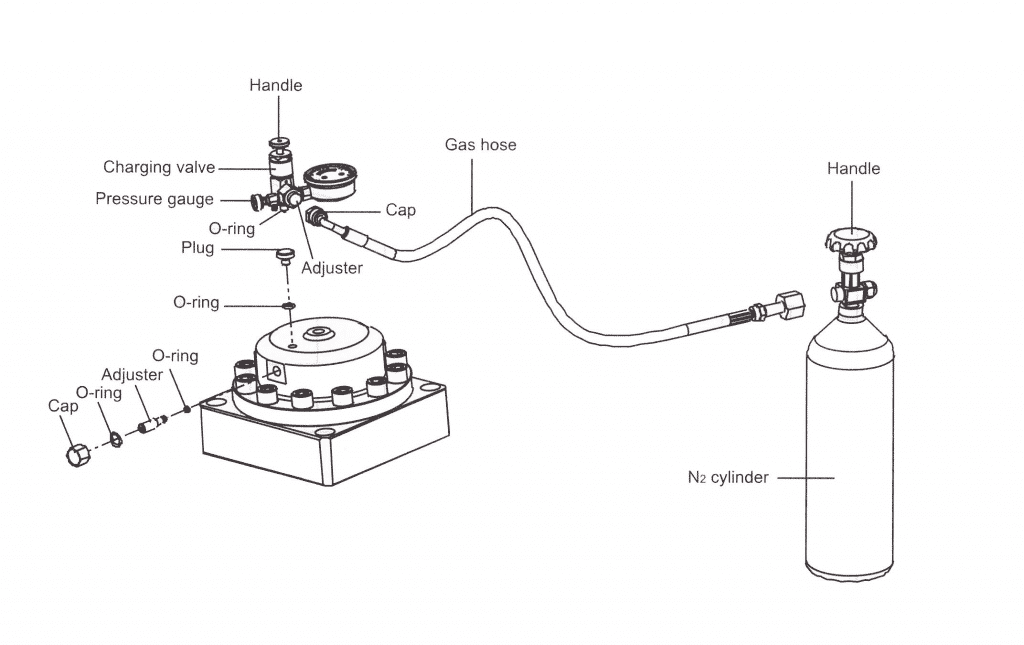

Why Hydraulic Breaker Need Nitrogen and How to Charge

Select Guide For Hydraulic Breaker Hammers – According to Productivity Rate

Tips to Maximize Hydraulic Breaker Life

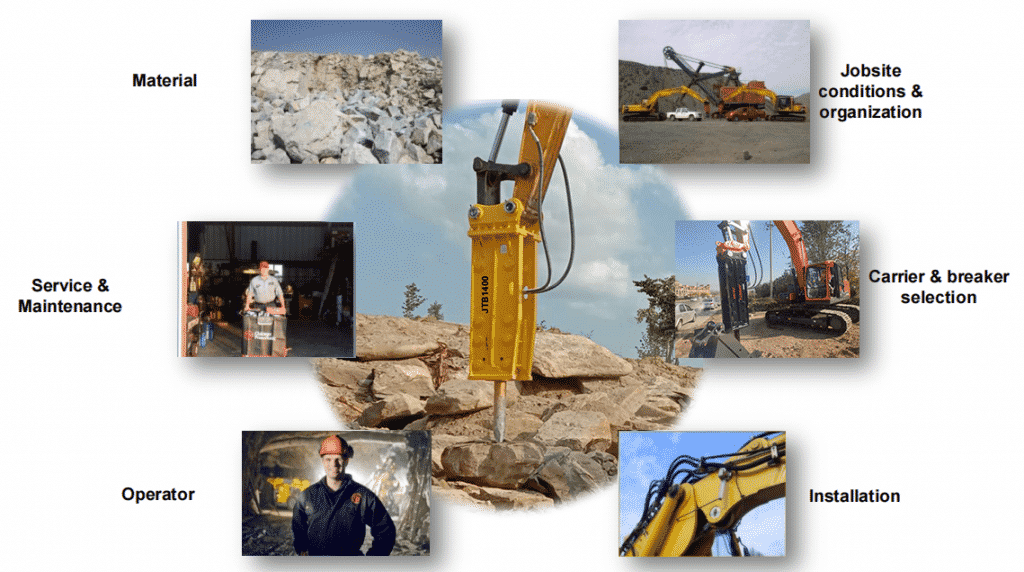

How To Select Hydraulic Breaker/Hammer For Your Program?

What is Hydraulic Breaker and How Does It Work?

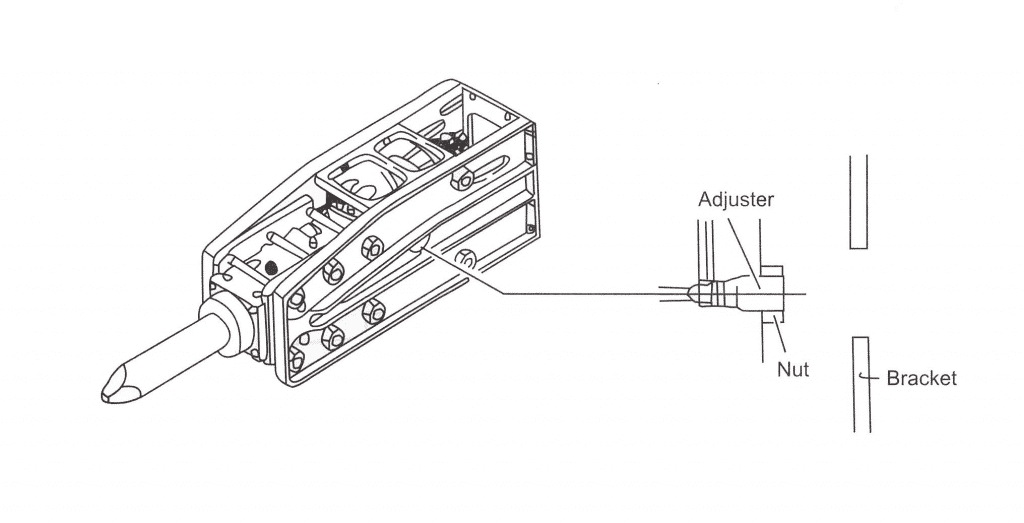

How to Adjust Hydraulic Breaker for Mini Excavator

Hydraulic Breakers Trouble Shooting and Solution