Tips to Maximize Hydraulic Breaker Life

People engaged in the excavator industry must be no strangers to hydraulic breakers.

For operators, choosing a hammer correctly, using the hammer correctly, and maintaining the hammer properly are basic skills. However, in actual operation, if it is not used properly, it will take a long time for maintenance and is very troublesome.

Recommended Reading: What is a Hydraulic Breaker and How Does It Work?

By following the below tips, you can get optimal performance and life out of your hydraulic breaker.

.Read More: The working principle of excavator attachments

- The Working Principle of Hydraulic Breaker

- The Working Principle of Excavator Ripper

- The Working Principle of Hydraulic Auger

- Hydraulic Grapple Working Principle

- The Working Principle of Quick Hitch Coupler

- The Working Principle of Skid Steer Tree Spade

- The Working Principle of Skid Steer Snow Throwers

1, No blank firing

During the operation of the hydraulic breaker, a few blank firing always occur, when the chisel fails to keep perpendicular (90 degrees) with the material being broken, fails to press the workpiece tightly or does not stop the breaker before the material separates.

No blank firing, since it will cause damage to parts.

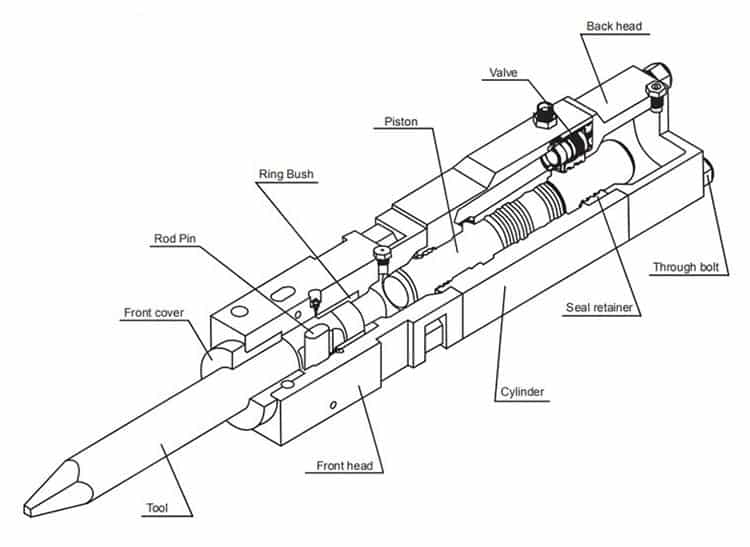

No oblique hitting, the chisel should be perpendicular to the broken object, otherwise, the piston will move in a non-linear manner in the cylinder, which will cause scratches on the piston and the cylinder.

Excellent performance with high durability. The company has been developed to meet the high standards of the current market. The demand for high durability and low maintenance costs on hydraulic equipment are combined in the total design of our attachments.

- Cylinder & valves: prevents scuffing with precision finishing treatment

- Piston: every piston tolerance machined perfectly according to each cylinder

- Chisel: 42CrMo, exceptional performance and reliability

- Seal kit: original NOK

2, No Chisel Shaking

No matter how long the old driver has been in the industry, nobody can do breaking work without shaking a bit of the chisel. Yet such behavior must be reduced as much as possible. Otherwise, over time, it will lead to damage to bolts and chisels.

In addition, bad habits such as the breaking hammer falling too fast and hitting the broken objects hard must also be corrected in time!

3, No working in water and sediment

In places such as water or sediment, the chance of using a hydraulic breaker is relatively small, but it does not exclude the possibility of construction under such conditions.

In such a case, we must pay attention to that except for the chisel, the rest of the hammer body can not be soaked in water or sediment.

The reason is very simple. The breaker itself is composed of precision components. These kinds of precision components are most afraid of the accumulation of water, mud, etc., which will seriously affect the performance of the piston and will cause the breaker to break quicker than it should be.

4, No Continuous operation

Sometimes when the project is urgent, the driver will work without interruption.

In such cases, to avoid high oil temperature and chisel damage, please pay attention don’t let the hydraulic breaker stay in one spot for more than 1 minute, when working on hard objects.

5, Don’t use a hydraulic breaker to push heavy objects

It is dangerous to push heavy objects by the hydraulic breaker, which will both damage the hydraulic breaker itself and may cause dangerous accidents such as the broken arm of the excavator, overturning and so on.

If the breaker of the same brand is maintained and used properly, the probability of failure will be very small, and the service life will be extended accordingly. Pay attention to details, not only save time but also save money!

JIANGTU Excavator Break adopts special carbon steel material and heat treatment processes to ensure that the wear of the piston hitting the surface is minimized and the service life of the piston is maximized.

Piston production adopts precise tolerance control to ensure that the piston and cylinder can be replaced with a single product, reducing maintenance costs.

The shell of the breaker has put forward higher and higher requirements for its sealing system. The NOK brand oil seals ensure our hydraulic breaker has low (zero) leakage, low friction and wear, and long service life.