What Is an Order Picker? | Bigrentz

An order picker is a class II electric motor narrow aisle truck. Also called a stock picker or selector, it’s designed to lift operators to inventory locations so they can manually place materials or retrieve them from designated storage areas.

These machines are typically used in warehouses, distribution centers, retail centers, fulfillment centers, and manufacturing plants.

If you have an indoor project that involves retrieving or stocking items, you might need to rent an order picker. It can offer mobility in narrow aisles where counterbalance forklifts or pallet trucks can’t navigate as easily.

In this post, we go over how an order picker works, and how it compares to other material-handling equipment.

Order Picker Uses

In addition to its namesake, there are many applications for order pickers in warehouses and distribution centers.

Order pickers are used for:

- Stocking and restocking products on shelves: With operators elevated on the machine, the stocking process is more precise and efficient.

- Picking products from storage for fulfillment: Order pickers allow workers to pick individual products to fill customer orders instead of having to load and unload whole pallets for the right item.

- Organizing products in storage: An order picker’s maneuverability and control makes it easier to organize inventory, including more fragile products, ensuring quality control.

- Unloading products from storage: Order pickers can navigate narrow aisles, making it possible to load and unload products in confined areas, whether they’re in warehouse storage or coming from delivery trucks.

Types of Order Pickers

There are three main types of order pickers:

- Low-level order pickers: These machines are best for picking operations at lower levels or shelves, with lift heights of up to 10 feet.

- Medium-level order pickers: These machines can reach mid-level heights for order picking, with lift heights ranging from 10 to 30 feet.

- High-level order pickers: These machines are made for high racking systems, with lift heights of up to 30 feet or even upwards of 40 feet for some models. They can be operated using rail or wire guidance.

There are also specialty order pickers, designed for specific tasks or types of products. Here are some of the most common ones:

- Furniture pickers: These pickers are designed to handle longer and heavier loads at higher heights, making them ideal for moving big, irregularly shaped objects like furniture. Typical fork lengths range from 42 to 96 inches with lift heights up to 30.5 feet.

- AGV order pickers: AGV stands for automated guided vehicles, meaning these machines can drive, tow, and even lift pallets on their own. They range in length from 59 to 148 inches and in height from 46 to 53 inches.

Order Picker Features

The typical order picker has the following features:

- Maneuverability: Can maneuver in tight spaces, especially in warehouses with narrow aisles

- Load capacity: Typically up to 3,000 pounds

- Driver position: 360 degrees

- Power source: Battery powered, usually 24, 36, or 48 volt battery

- Indoor/outdoor: Typically used indoors

- Uses: Stocking, picking, unloading, and organizing products from warehouse shelves or distribution centers

- Lift height: Up to 45 feet

How Does an Order Picker Compare to Other Equipment Types?

Though they’re sometimes called order picker forklifts, order pickers differ quite a bit from other machines in the forklift family. Here’s how this piece of equipment stacks up with other material-handling machines.

Forklift

A forklift is a powered industrial vehicle that is used to lift and transport palletized materials. While you can use electric forklifts conveniently indoors, you use them for much heavier, fuller loads, but an order picker grabs individual items from shelves to fulfill specific orders.

- Choose a forklift over an order picker if: You have heavy pallets or bulky loads that need to be moved or stacked, rather than specific item retrieval.

Explore All Forklifts

Reach Truck

A reach truck is a type of forklift that is designed to reach into and retrieve pallets from racking systems in warehouses. It differs from an order picker because it’s primarily used for moving and stacking pallets on high racks. Unlike how stock pickers elevate the operator for more precise picking, a reach truck operator is typically at the bottom of the machine.

- Choose a reach truck over an order picker if: You need to move, stack, or retrieve full pallets from tall or deep storage racks instead of picking individual items.

Scissor Lift

A scissor lift is a machine with crisscrossing mechanisms that raise and lower the platform vertically. It’s typically used for elevating multiple workers and their tools vertically for maintenance-type tasks, whereas an order picker elevates single operators for work in narrow warehouse and shelving areas.

- Choose a scissor lift over an order picker if: You have a task that requires vertically elevating multiple people and tools, like painting, maintenance, or construction.

Explore All Scissor Lifts

Boom Lift

A boom lift, also known as a cherry picker, is a type of aerial lift. It lifts workers up on a platform vertically or horizontally so they can reach different angles in a workspace.

A boom lift has much greater height capacities and can help access hard to reach areas. It’s often used in applications like cleaning and maintenance, painting, roofing, and electrical line repair.

Since boom lifts aren’t compact like stock pickers, they’re primarily used in larger spaces, indoor or outdoor. Order pickers, on the other hand, are best suited for elevating workers so they can reach shelving in narrow warehouse aisles.

- Choose a boom lift over an order picker if: You have an indoor/outdoor project that doesn’t involve working in narrow areas and requires more versatility in reach.

Explore All Boom Lifts

When to Choose an Order Picker

If your project involves any of the following, you might want to choose an order picker:

- You need to selectively pick or restock items. Order pickers are great for precisely picking individual items. If you’re picking items one at a time instead of entire pallets, you’ll benefit from an order picker.

- You need to quickly navigate in narrow spaces. Because of their compact size, order pickers can navigate very narrow aisles on sites like warehouses more easily than forklifts or other larger machines. They’re also better for frequent transitions between different storage areas than machines used for loading and unloading.

- You need to access products stored on high racks. If you’re picking items from high shelves or storage racks in a warehouse, order pickers provide the height and precision you need to access product safely.

- You want to improve efficiency. The need to pick individual items over bulk goods is only increasing thanks to the rise of eCommerce. Order pickers can handle these needs quickly and efficiently, improving labor and warehouse optimization and automation.

- You want to improve accuracy and safety. Elevated operator platforms provide operators an unobstructed view of inventory for more accurate and safer picking.

Safety Requirements for Using an Order Picker

An order picker may not be the most heavy-duty machine, but it’s still important to be sure you’re using it correctly to keep everyone safe. Here are some basic safety requirements for using an order picker:

- Wear PPE and a safety harness. When you’re using an order picker, you should be wearing PPE like safety goggles, slip-resistant boots, gloves, hard hats, and high-visibility vests. Wear a harness to stay secured in the machine.

- Be properly trained and certified. Like all forklift operators, anyone who operates an order picker has to be trained and certified to do so.

- Check the order picker’s condition before use. Make sure the device is in good working condition before you use it, both in terms of its integrity, no obvious physical damage, and function.

- Maintain clear visibility during operation. Make sure the area you’re using the machine in is free of obstructions, and that you have a clear view of what’s in front of and around them.

Common Mistakes to Avoid When Operating an Order Picker

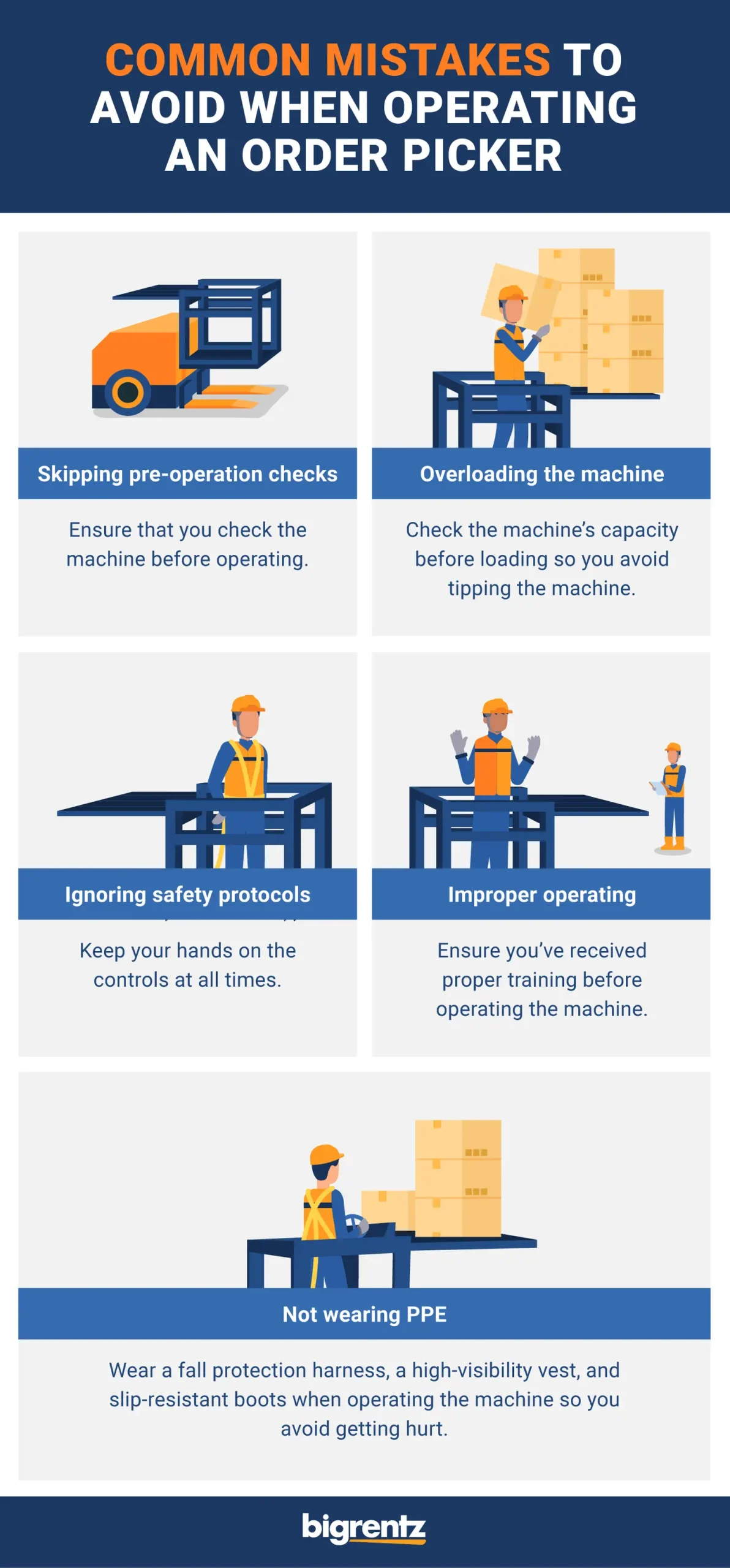

In addition to keeping safety requirements in mind, you’ll also want to watch out for these common mistakes:

- Skipping pre-operation checks: It’s crucial to check the machine before you start working with it to ensure it’s safe to operate.

- Overloading the machine: Don’t load more on the machine than it can handle. Check its load capacity before loading it so you avoid tipovers and other potential hazards.

- Ignoring safety protocols: Follow all safety requirements when operating the machine. Keep your hands on the controls at all times.

- Improper operating: Make sure the person who uses the order picker is fully trained and certified to operate one. Also, make sure your worksite has necessary safety measures in place, like defined traffic lanes.

- Not wearing PPE: Wearing PPE keeps you safe while you use the machine, especially in the event of an accident or malfunction.

Order Picking Methods

Order pickers are designed for quick and efficient item picking in warehouses and distribution centers. To maximize efficiency, these machines support multiple types of order picking.

The method that works best for you depends on your task: what type and quantity of product you’re picking, where you’re getting it from, and how fast you need to move.

Here are some of the main methods to consider:

- Batch picking: This method groups multiple orders into small batches. A worker picks items for all orders within the batch in one pass. It’s a good method to use when you’re dealing with multiple orders for the same or similar items.

- Zone picking: This method divides the warehouse into zones, assigning specific pickers to each one. Each picker is responsible for picking items only within their zone. Orders move from one zone to the next through conveyor systems or manually until they’re complete.

- Wave picking: This method combines zone and batch picking. Workers pick items in batches within their zones. Picking is coordinated across zones in waves to ensure accurate and efficient order consolidation.

Working as an Order Picker

“Order picker” isn’t just the name of the machine — it’s also a job title in its own right.

Order pickers are the people responsible for selecting items and preparing orders for shipment. They use equipment like order pickers and need the proper certifications to operate them. The job can be physically demanding, requiring movement around the warehouse and lifting items of various weights and sizes.

OSHA has training requirements for operators, consisting of formal instruction, practical hands-on training, and a final performance evaluation. The training program takes less than a month to complete.

Responsibilities include:

- Safely operating material handling equipment

- Picking orders with the help of computerized systems or lists

- Ensuring the correct items are picked and organized on pallets or carts

- Wrapping and securing pallets for transport

- Maintaining warehouse cleanliness and following safety guidelines

Ready to Rent an Order Picker?

If you’ve got a job that requires precise, organized item picking, an order picker might just be the right piece of equipment for you. For all your material-handling needs, from forklifts to boom lifts, BigRentz has you covered. Rent one of our lift trucks for as low as $250 a day or choose another pricing option that gives you the equipment you need to increase efficiency and decrease downtime for your operation.