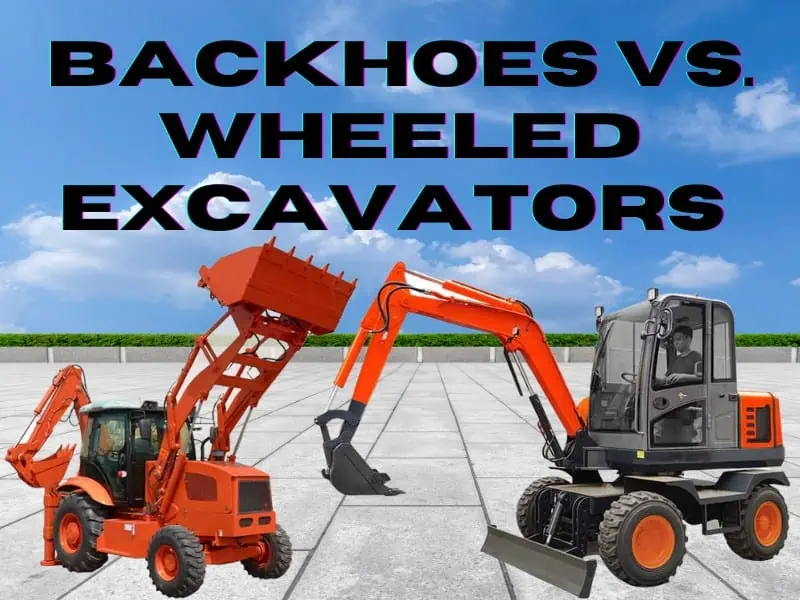

Backhoes Vs. Wheeled Excavators Which One Should We Choose?

Backhoes vs. wheeled excavators are essential pieces of heavy machinery in construction and excavation. Both machines have their advantages and disadvantages, and the choice between them ultimately depends on the specific needs and requirements of the project at hand.

There is an increasing trend among backhoe customers towards opting for compact wheeled excavators, as they offer comparable features and specifications to backhoes. Their mobility makes them an attractive option for customers who typically do not require a full-sized wheeled excavator. Furthermore, many backhoe customers primarily use the wheeled machine function and infrequently utilize the loader.

What is a backhoe?

They are compact, versatile machines commonly used to dig and grade residential and urban areas. They have a relatively small depth and reach, making them well-suited for digging trenches, foundations, and around utilities. These are also relatively low-cost, making them popular for smaller construction projects and landscaping work. Additionally, they are easy to operate, requiring minimal training and skill.

Uses of Backhoe

They, like excavators, are well-suited for digging through rough terrain and handling heavy or dangerous materials. While they are not ideal for heavy-duty excavation tasks, the operator can utilize the front loader to transport or move heavy objects.

The versatility of machines extends beyond the construction industry, with farmers also employing them for soil tilling and other farm-related projects. It highlights machines’ versatility and adaptability to various applications and industries.

What is a wheeled excavator?

It is a type of heavy equipment machinery used in construction and mining operations. It consists of a cab that sits on top of a chassis with wheels instead of tracks. The cab is equipped with a rotating upper structure that houses an arm, called the boom, and a digging implement, such as a shovel or bucket.

It allows the machine to move around a job site without damaging surfaces and provides greater mobility on roads and highways. Wheeled excavators are often used for digging, grading, and loading material and are versatile machines that can perform various tasks in the construction industry.

Uses of the wheeled excavator

They are becoming increasingly popular in recent years. These machines offer several advantages over their tracked counterparts of the same size:

- It offers greater maneuverability in tight areas, making them ideal for working in urban or densely populated environments.

- Their faster movement across a work site improves productivity and efficiency.

- They have a lower impact on the work ground, reducing the potential for damage to the surface and making them more suitable for sensitive environments.

These benefits have contributed to the growing popularity of machines in recent years, making them an increasingly attractive option for construction and other heavy industries.

Difference between Backhoes vs. Wheeled Excavators

Job site conditions

When choosing between a backhoe and a wheeled excavator, it is important to consider the type of work being done and the job site conditions. If the job requires a lot of digging, grading, and excavation work, then a wheeled machine is likely the better choice.

A backhoe may be the better choice if the job requires a compact machine that can fit into tight spaces and maneuver around obstacles. Additionally, the availability of skilled operators and the cost of each machine should also be considered.

Cost

In terms of cost, backhoes are generally less expensive than other machines However, it is important to remember that the cost of operating a machine includes not only the initial purchase price but also maintenance, fuel, and labor costs. Wheeled excavators are generally more fuel-efficient and require less maintenance than other machines, so it is important to consider these factors when deciding.

Engine power and digging forces

It is important to understand that the horsepower rating for backhoes does not necessarily reflect their digging power, particularly at the excavator end. This number only indicates the power required for the front bucket, which can be misleading.

When evaluating digging equipment, it is crucial to consider your specific excavation requirements, including maximum digging depth. Although some have a limited digging depth of 10 feet 10 inches and a reach of 19 feet 11 inches, they can still be suitable for a wide range of applications.

Working range and repositioning

Working in tight spaces can present challenges for maneuvering heavy equipment. The 180-degree working radius of a backhoe, as compared to its 360-degree working radius of it, can make it more difficult to navigate in these conditions.

The added flexibility gives the operator more options for dumping material and loading trucks and greater ease in trenching. With this, the operator can push the travel pedals with their feet to reposition the machine, allowing for continuous digging without the need for repositioning the equipment. This added convenience and flexibility can greatly improve efficiency and productivity in tight spaces.

Specific tasks

Ultimately, the choice between both machines depends on the tasks needed at your work site. While both machines have different attachments, excavators tend to have more specialized and unique attachments to meet specific job requirements.

However, if you do not have any specialized needs, a backhoe may be more versatile and suitable as it can serve a broader range of functions.

If you are still trying to decide which machine to choose, seek the opinion of a construction expert. EquipmentShare’s branch locations are staffed by experienced professionals who can assist you in finding the solution that best fits your needs and maximizing efficiency on your job site.

Operator’s level

Another factor to consider when choosing both is the operator’s experience level and the availability of skilled operators in the area.

They are generally easier to operate than wheeled excavators, which require a higher level of skill and training to use effectively. A backhoe may be better if the operator is inexperienced or the skilled labor market is limited.

Rotation

Wheeled machines have a wider range of rotation, allowing the entire machine’s chassis and arm to rotate in a complete circle. It provides greater flexibility and maneuverability for the operator. On the other hand, backhoes have a more limited rotation range, with the arm pivoting across a range of approximately 200 degrees.

Gain a comprehensive understanding of the capabilities and limitations of both machines. Consulting with heavy equipment professionals, who are knowledgeable in both, as well as their various attachments, can also provide valuable insight and recommendations tailored to your specific project needs.

Can Backhoe be used for Excavation?

Yes, backhoes are commonly used for excavation projects, particularly for smaller to moderate-sized projects such as digging a residential basement. However, it is important to note that excavators are often more suitable for heavy-duty projects, such as mining or large-scale construction.

What are the Differences in Control Systems between Backhoes vs. wheeled Excavators?

The control systems of backhoes vs wheeled excavators can sometimes need clarification as they vary. Backhoes typically offer two operating systems: pilot control and lever control. The pilot control system uses buttons to maneuver the machine, while the lever control system uses two side levers that can be pushed in different directions to control the backhoe. On the other hand, wheeled excavators typically only use lever control systems.

Bottom line

In conclusion, choosing backhoes or wheeled excavators depends on the specific needs and requirements of the project at hand. If you want more detail, you can contact us. But it is important to consider factors such as the type of work being done, the job site conditions, the operator’s experience and skill level, and the cost of each machine. By carefully considering these factors, you can ensure that you choose the right machine for your construction or excavation project.