Electric vs Non-Electric Mini Excavators: Making the Right Choice- Hydraulic Pulverizer

Keywords: excavator fork attachment, auger attachment for excavator

With the growth in electric vehicles across multiple industries, more and more electric equipment is being made for construction and landscaping. Mini excavators were the first construction equipment to have electric options. They have seen the most development over the last few years.

Mini excavators are used on almost every residential and commercial landscaping or construction project in some capacity. With government regulations starting to require fewer emissions, determining whether you need an electric or diesel mini excavator is important. These factors will only increase in the coming years as a wider range of heavy equipment has electric options.

Overview of Electric Mini Excavators

With the growth of electric excavators in the market, understanding how they work, when they work best, and the benefits of using them is important.

How Electric Excavators Work

The main difference between electric and non-electric mini excavators is the engine. Electric compact excavators have lithium-ion batteries that power the machine including the hydraulics and attachments. They do this by converting the power received from the battery into mechanical energy which gets transferred to the hydraulic pumps that power the arms and buckets.

Find Your Next Equipment Rental on DOZR

2 ton, Mini Excavator Rentals

1.5 ton – 9 ton

3 ton, Mini Excavator Rentals

1.5 ton – 9 ton

4 ton, Mini Excavator Rentals

1.5 ton – 9 ton

SEE ALL EQUIPMENT ON DOZR

Batteries typically hold enough power for about 4 to 5 hours of work and require up to 12 hours to charge.

Typical Applications

Some common applications for these machines include:

- Zoos: Because of how quiet they are, they don’t intimidate the animals as much when groundskeepers have to do their work. Volvo has a use case of how they’re being used at the Toronto Zoo.

- Indoor demolition: As they don’t produce harmful emissions and are typically much quieter, they are great options for indoor use.

- Hospitals: With government regulations becoming more strict on emissions, electric machines are great for projects that have noise and vibration requirements like hospitals. We had a project manager from EllisDon on our podcast to talk about all the challenges in finding the right equipment for hospital construction.

- School zones: Often in residential areas, school zones are another noise-sensitive area where local governments try to restrict emissions as much as possible which is why electric machines are common.

Advantages and Disadvantages

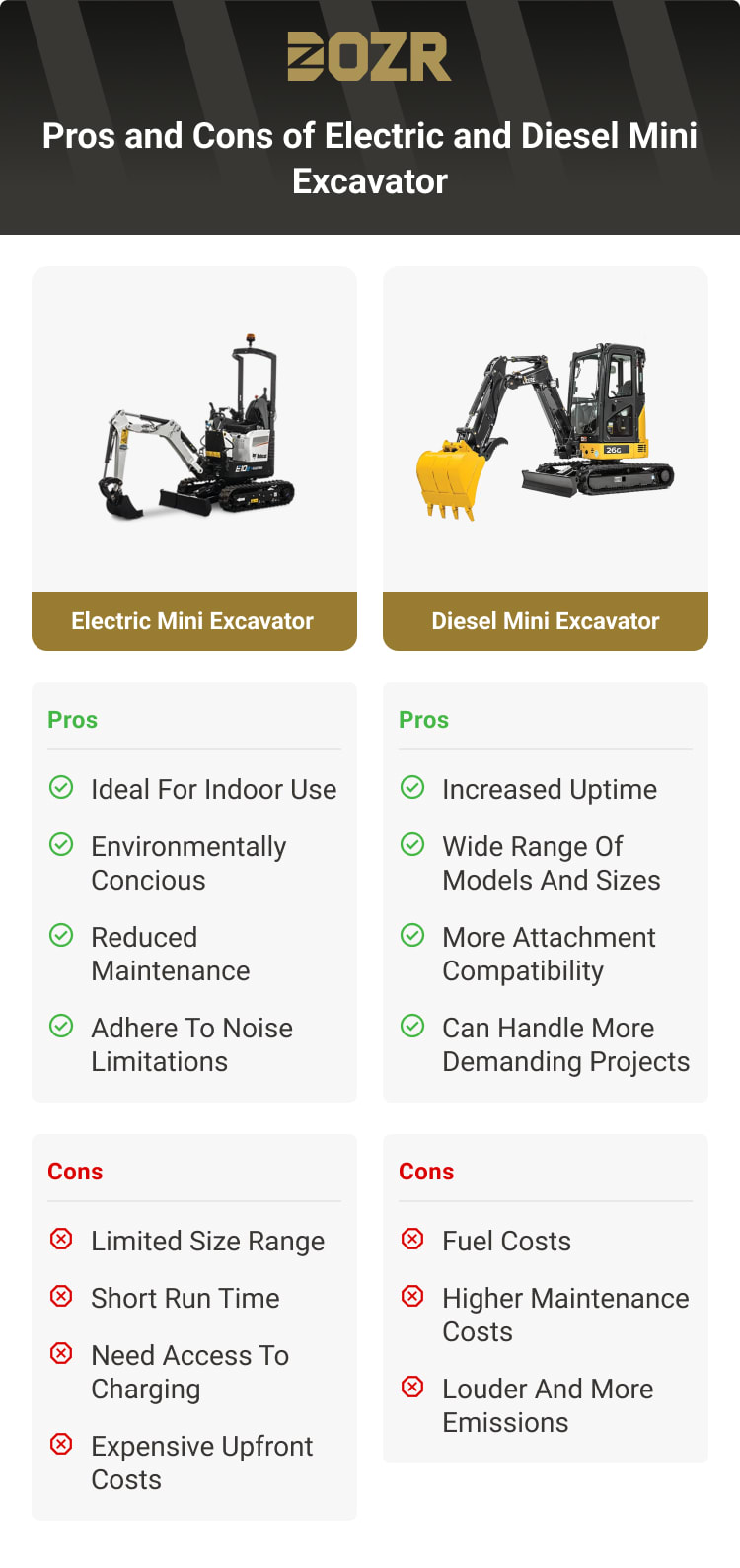

While electric construction equipment is widely considered to be the future of construction, many advantages and disadvantages exist.

On the advantages side, they’re quieter, more environmentally conscious, and have fewer exhaust fumes. This aligns them with the strict environmental regulations that continue to be passed.

Bobcat E32e mini excavator on display at ConExpo

However, the battery charge only lasts 4 to 5 hours as of the current models and takes 12 hours to recharge. This can be a full day of work for most operators, but it really depends on your utilization rate. A smaller contracting company may need to rely on one piece of equipment more than someone with multiple machines.

A second disadvantage is that the charging infrastructure is currently not where it needs to be to support electric equipment. Many construction jobs take place in remote areas, far away from any plugs. And if you’re in a residential area, your client may not appreciate you putting an increase on their electricity bill.

Another factor is if you’re renting. Electric equipment isn’t in every equipment company’s fleet because of how new it is. They are expensive upfront and it’s unclear if they’ll be utilized as much as diesel-powered mini excavators.

The last disadvantage is that most electric mini excavators are not the most capable machines. Volvo has the ECR25, which was the first non-diesel model and is only a 3-ton mini excavator. JCB has the 19C-1E which is only a 2-ton mini excavator. There is still a lot of work to be done in making more powerful variations of electric compact excavators.

Benefits of Electric Excavator Rental

One of the primary benefits of renting an electric mini excavator is saving on fuel costs. As one of the highest costs, trying to limit fuel consumption can do great things for a contractor’s bottom line. This can also increase the chances of winning a bid. Other benefits include reduced noise and emissions, reduced downtime and maintenance, and a lower carbon footprint.

Overview of Non-Electric (Diesel) Mini Excavators

Because of everything mentioned above, diesel excavators are still the primary choice for many contractors looking for equipment for projects. Here’s a breakdown of their applications, pros and cons, and benefits.

How Diesel Excavators Work

Using a gas-powered engine, hydraulic fluid is sent to the hydraulic pumps and cylinders that control the excavator’s arm and bucket.

Typical Applications

Compact excavators can be used for almost any job. Whether it’s offering support on large land clearing projects, digging trenches, small demolition, landscaping, or making pools in residential areas, mini excavators are one of the most commonly used machines. They have been mostly replaced by electric options for indoor use.

Advantages and Disadvantages

The advantage of having a gas-powered mini digger on site is the opposite of all the electric model’s disadvantages. Because they don’t require a recharge, they can be utilized more on-site with a quick refuel, giving them more runtime. They also have a wider range of specs, all the way up to 10 tons, giving them more dig depth, power, and lift capability.

Kobelco mini excavator digging and moving dirt on a project

Non-electric mini excavators also are very common for equipment rental companies to own in their fleets. Because they’re so commonly used, they are an essential machine to have on hand at any given moment.

As for disadvantages, fuel costs are one of the biggest costs on any job site. This is a necessary expenditure but within the next few years, fuel costs should decrease as more alternatives get developed.

Another disadvantage is how loud they are and how much emissions they have. As governments create more regulations, this will continue to hurt contractors who don’t make the leap to more emission-friendly options.

They typically have more maintenance and repair costs. This is because gas-powered excavators have more parts including the transmission and exhaust system, which require more maintenance.

Benefits of a Diesel Mini Excavator Rental

The biggest benefit of renting gas-powered mini excavators is that they are more accessible than electric models. This makes them easier to find when you’re in a pinch and need equipment fast. Another positive is that mini-excavators come with a wider range of specs, allowing them to fill the gap on more projects.

Comparing Electric and Non-Electric Mini Excavators

We’ve talked a lot about these two types of machines and now it’s time to summarize them simply.

Performance and Efficiency

The main thing to consider when it comes to performance is, as of right now, gas-powered mini excavators have a wider choice of options. Ranging from 1 ton to 10 tons, they can be used for essentially any residential or commercial project.

On the other hand, electric models only go up to 3 tons in size. This means they have limited reach, dig depth, and power in comparison to non-electric excavators. That ultimately means that diesel excavators have better performance and efficiency. However, the electric versions of the 1-ton and 2-ton sizes don’t lose any specs compared to their gas-powered counterparts.

Environmental Impact

Because electric excavators don’t require fuel, they have a better environmental impact than fuel-powered excavators. According to ForConstruction Pros, construction equipment represents just over one percent of global emissions. While it’s mostly large machines that make this dent, compact models like mini excavators are factored in as well. The hope is that the transition to electric equipment will decrease the number of emissions year over year.

Operating Costs and Maintenance

Fuel costs continue to rise and that puts an emphasis on contractors to try to eliminate using it where possible. This also puts pressure on manufacturers to stay competitive and make more electric equipment.

One of the primary advantages of electric equipment is that they have fewer parts, mainly the transmission and exhaust system. This is great because the elimination of these parts decreases both operating and maintenance costs.

Kubota mini excavator idle on a project

Electric engines also reduce the need for fuel, have lower engine run times, and reduced energy waste. The maintenance costs are also lower as batteries require almost no maintenance. However, if the battery breaks, it can be expensive to repair. They also are more expensive upfront, and having access to upfront cash can be a huge challenge for contractors.

Noise and Vibration Levels

A significant amount of jobs that require mini-excavators take place in residential areas. Unfortunately for contractors, this often means the headache of finding equipment that has limited noise and vibrations. Or again, in the case of working on an active hospital redevelopment project, requires it.

Fortunately, electric mini excavators create less noise and have reduced vibration levels. This can be beneficial in many circumstances. Also, more regulations are being passed about noise levels on a construction site and restrictions can limit the options for contractors.

Choosing the Right Mini Excavator for Your Project

Factors to Consider

There are a few things to consider when picking between these excavators: the environment, the specs required, costs, and availability.

Each of these will play a part in determining which version of the machine will work best for you. Working indoors? An electric model will get the job done. Not only from an emissions perspective but also because the models are small and can fit through doors easily.

Need a certain amount of power and dig depth? This will affect whether there’s even an electric model that fits those specific requirements. Trying to cut down on fuel costs? That’s an easy factor in choosing an electric model.

These are all important things to consider and every job site will have different limitations.

Conclusion

Overall, electric equipment still has a ways to go before its general adoption into everyday use. Some great applications make electric models worth the choice. However, they also have some major disadvantages in comparison to non-electric models right now including spec diversity and availability.

Renting the right equipment is important. You don’t want to have any issues where you realize the equipment you have isn’t going to help you get the project done.

It’s worth connecting with the sales team of the rental company for expert advice when trying to pick the right equipment. Contact DOZR’s team with any additional questions to see what mini excavator rental is right for you.

MktoForms2.loadForm(“//378-ZTK-807.mktoweb.com”, “378-ZTK-807”, 1093);