MB Crusher’s Crushed Granite Demos, New Products at MINExpo

var addthis_product = ‘wpp-262’;

var addthis_config = {“data_track_clickback”:false,”data_track_addressbar”:false};if (typeof(addthis_share) == “undefined”){ addthis_share = [];}

As a newcomer to MINExpo, the American subsidiary of MB Crusher in Italy gave live performances of its crushing attachment and displayed a drum cutter and screening attachment designed for loaders at its booth. This was the first time the subsidiary displayed its drum cutter and loader screening attachment product lines at an exhibition.

MB Crusher America, Inc. had live crushing demonstrations of the BF135.8 crusher attachment on a Hyundai excavator. It crushed granite to a 4-inch minus for MINExpo attendees. The BF135.8 crusher attachment is designed for excavators weighing over 94,000 pounds. It has an adjustable output setting from a 1.5-inch minus to a 6-inch minus. The productivity rate can get up to 115 cubic yards per hour, about 170 tons per hour, at a 6-inch minus output adjustment.

“We had people tell us during the demo that they have not seen a machine like our BF135.8 crushing attachment. It’s a machine we believe will help miners with their jobs,” Miriano “Max” Ravazzolo said, C.E.O. of MB Crusher America. “Our BF90.3 crusher bucket is being used by Kinross at Round Mountain Gold for its gravity plant. And our BF150.10 crusher bucket is being used by a major mining company!”

On the other side of its booth, the company displayed its MB-R800 drum cutter and MB-LS170 screening attachment. Both are new products created within the year.

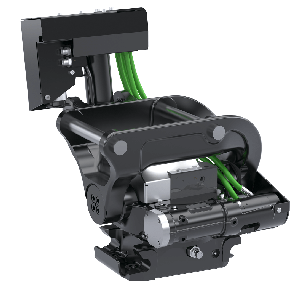

The MB-R800 drum cutter has a direct drive twin-motor system and runs on the hydraulic system of the excavator. It is designed to cut, grind, mill, or till surfaces and hard materials. The drum cutter is used in these areas of application: demolition, refurbishment, trenching, quarries, excavating, special foundations and road building.

The MB-R800 drum cutter has a direct drive twin-motor system and runs on the hydraulic system of the excavator. It is designed to cut, grind, mill, or till surfaces and hard materials. The drum cutter is used in these areas of application: demolition, refurbishment, trenching, quarries, excavating, special foundations and road building.

The MB-LS170 screening attachment is designed for wheel loaders and backhoe loaders weighing between 14,000 and 24,000 pounds. It has a load capacity of 1.6 cu. yd. and a basket depth of 35 in. It is created with a cone-shaped basket to increase production and allow contractors to quickly sift through material without residue. The MB-LS170 can screen mixed materials, sift wet and dry materials, and clean superficial powder from natural stones.

In the past year, the company has expanded its product line to include several models and sizes of grapples, drum cutters, and a new line of screening attachments designed for skid loaders, backhoes and loaders. In addition to its expansion, MB offers magnetic separators and dust suppression kits for its crushing and screening attachments, which just last year was not an option for screening attachments.

MB’s attachments are ideal for quarries and mines, mineral processing, on-site processing, gold mine projects and gravity plants. Besides the mining industry, MB products have a wide scope of work that includes demolition, excavation, road work, pipeline work and environmental reclamation projects.

For information, visit MB America’s website at www.mbamerica.com, or contact the company at 855-MB-CRUSH (855- 622-7874). Federal customers can purchase MB’s products through the GSA Advantage! catalog at http://bit.ly/mbgsagov or through its contract number, GS-30F-007DA.

About MB Crusher

MB Crusher is the worldwide leader in producing and distributing equipment and accessories for the fields of earthmoving, demolition and recycling. MB America, Inc. is located in Reno, Nevada and is the American subsidiary of MB Crusher S.p.A. MB Crusher S.p.A. was established in 2001 in Italy and sells to over 150 countries through its dealers and distribution networks.