The Advantages of Hydraulic Quick Couplers in Excavation Equipment

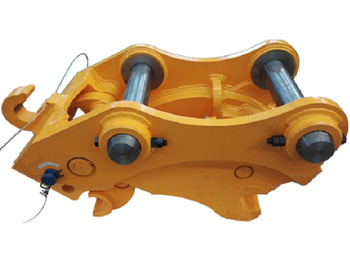

Hydraulic Quick Coupler

In the world of excavation equipment, efficiency and productivity are key factors for successful operations. One innovation that has significantly improved the versatility and speed of excavators is the hydraulic quick coupler. This powerful attachment allows operators to rapidly change between different tools and attachments, ultimately streamlining work processes and enhancing overall performance. In this post, we will explore the advantages of hydraulic quick couplers and their impact on excavation equipment.

Swift Tool Changes

Gone are the days of manual tool changes that ate up valuable time on the job site. Hydraulic quick couplers offer a seamless and efficient way to switch between various types types of excavator attachments, such as buckets, breakers, thumbs, hydraulic magnets and augers. With a simple push of a button or lever, the coupler securely locks or releases the attachment, allowing operators to rapidly adapt to changing tasks and work conditions. This swift tool change capability minimizes downtime, boosts productivity, and maximizes the utilization of the excavator.

Increased Operator Safety

Safety is paramount in any construction or excavation project. Hydraulic quick couplers contribute to safer operations by reducing the need for operators to manually handle heavy attachments, thus minimizing the risk of accidents and injuries. Instead of relying on manual connection methods, which often involve physical exertion and potential hazards, the hydraulic coupler provides a secure and reliable connection with minimal operator intervention. This automated process promotes a safer working environment for operators and crew members.

Enhanced Equipment Versatility

Excavators equipped with hydraulic quick couplers become highly versatile machines capable of performing a wide range of tasks. The ability to swiftly switch between attachments allows operators to optimize the excavator’s functionality based on specific project requirements. For example, an excavator can effortlessly transition from digging and trenching with a bucket attachment to breaking concrete or compacting soil using a hydraulic breaker or compactor attachment. This versatility enables operators to tackle diverse tasks efficiently, eliminating the need for multiple machines on the job site.

Time and Cost Savings

Time is money in the construction industry, and hydraulic quick couplers deliver substantial time savings. By eliminating the need for manual attachment changes, operators can complete tasks more quickly and efficiently. Reduced downtime translates into increased productivity and cost savings. Additionally, the versatility of a single excavator with quick couplers eliminates the need for additional equipment, reducing capital costs and operational expenses associated with multiple machines.

Conclusion

Hydraulic quick couplers have revolutionized the way excavators operate, providing significant advantages in terms of efficiency, safety, versatility, and cost savings. The ability to swiftly change attachments enhances productivity, while the automated coupling process promotes operator safety. Moreover, the versatility of a single excavator with quick couplers eliminates the need for multiple machines, optimizing project timelines and reducing costs. Incorporating hydraulic quick couplers into excavation equipment is a smart investment that improves overall performance and maximizes the potential of these powerful machines.

Excavator Coupler Types

Manual Couplers

The most basic type of excavator coupler is the manual coupler. These units require the operator to physically exit the machine and manually secure the attachment to the excavator’s front. While manual couplers are simple and cost-effective, they can be time-consuming and present safety risks for the operator.

Hydraulic Couplers

A more advanced option is the hydraulic coupler. These couplers utilize the excavator’s hydraulic system to automatically engage and disengage attachments from the comfort of the cab. Hydraulic couplers offer significant productivity and safety advantages, allowing operators to swap tools without leaving the machine.

Hydraulic couplers come in two main varieties:

- Hydraulic Pin Grabber Couplers – These couplers use hydraulic cylinders to grasp the attachment’s pins, securing it to the excavator.

- Quick Coupler Systems – These more complex couplers feature a hydraulic mechanism that can pick up, rotate, and release different attachment types.

Tilt Rotator Couplers

An increasingly popular option is the tilt rotator coupler. This advanced system not only provides hydraulic attachment coupling, but also allows the operator to tilt and rotate the attachment 360 degrees. This added flexibility enables the excavator to perform tasks like precise placement, angled digging, and lateral positioning.

Tilt rotator couplers are ideally suited for specialized applications like demolition, landscaping, and utility work, where the ability to orient the attachment is crucial.