The New 1-2 Tonne Hydraulic Quick Coupler

1 2 hydraulic quick coupler

Keywords: hydraulic quick coupler, 1 2 hydraulic quick coupler

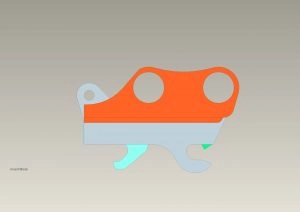

Our company is proud to present to you the new quick coupler for 1-2 Tonne Excavators. Adding this coupler to the HYpulverizer portfolio completes the HYpulverizer range for 1-85 tonne hydraulic quick couplers, offering you the customer the full package for your excavator fleet.

It may seem unnecessary to create a smaller hydraulic quick coupler for 1-2 tons because we currently have a large selection of 4-85 tons available, but that couldn’t be further from the reality.

Our engineers were aware from the beginning that this was a whole new product initiative. Indeed, it is just as durable, safe, and functional as the others, but this coupler needed to be revamped, reengineered, and re-invented for this particular coupler size.

hydraulic quick coupler

Martin McCormack was the lead engineer assigned to this project where not only was he designing and drawing this product but also hands on in the workshop where he trialed and tested different elements with the rest of the team.

I sat with Martin and asked him some questions on the project.

How do you feel about the end product now that it has been launched?

“To be honest I’m feeling good about the new coupler, we had set ourselves some really difficult challenges by committing to develop a coupler for this machine range but I strongly believe we more than exceeded our goals.“

What were the challenges with creating a coupler of this size?

If you think about the pin centre range for a minute, it starts at 90mm, my current phone measures 140mm long!!! This gives you a sense of scale when you talk about the QC25-30.

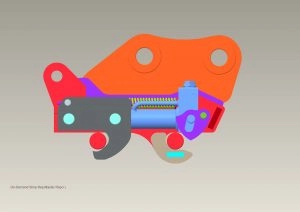

All our current couplers moves in a totally linear direction but this simply would not work here, we needed to come up with a concept that would retain the advantages of our sliding system but allow us to get back to 90mm pin centre.

We solved this problem very simply by coming up with a ‘slide and rotate’ wedge action.

The wedge retracts past the 90mm pin position and then rotates upwards following a machined slot in our pick up fittings, that’s it!

Early on we realised that rigorous testing would be required to ensure confidence that the coupler could survive ‘on site’ and in all conditions.

We custom designed and built test benches in our workshop and I have personally spent many hours running a series of tests based on real life scenarios that we have met ‘in the field’.

This testing has been invaluable from a design point of view as it allowed us to make tweaks on small parts of the design but also gave us much more confidence in the product, it really is a product we can stand behind and be proud of.”