The Ultimate Guide to Excavator Bucket: Types and Their Applications

Excavator buckets/ types of buckets

Are you looking for the most efficient way to move earth or dig trenches? Look no further than an excavator bucket! But with so many types available, how do you choose the right one for your project? Fear not – this ultimate guide is here to help. We’ll explore the different types of excavator buckets and their applications, giving you all the knowledge you need to make an informed decision. So grab a hard hat and let’s get digging into this exciting topic!

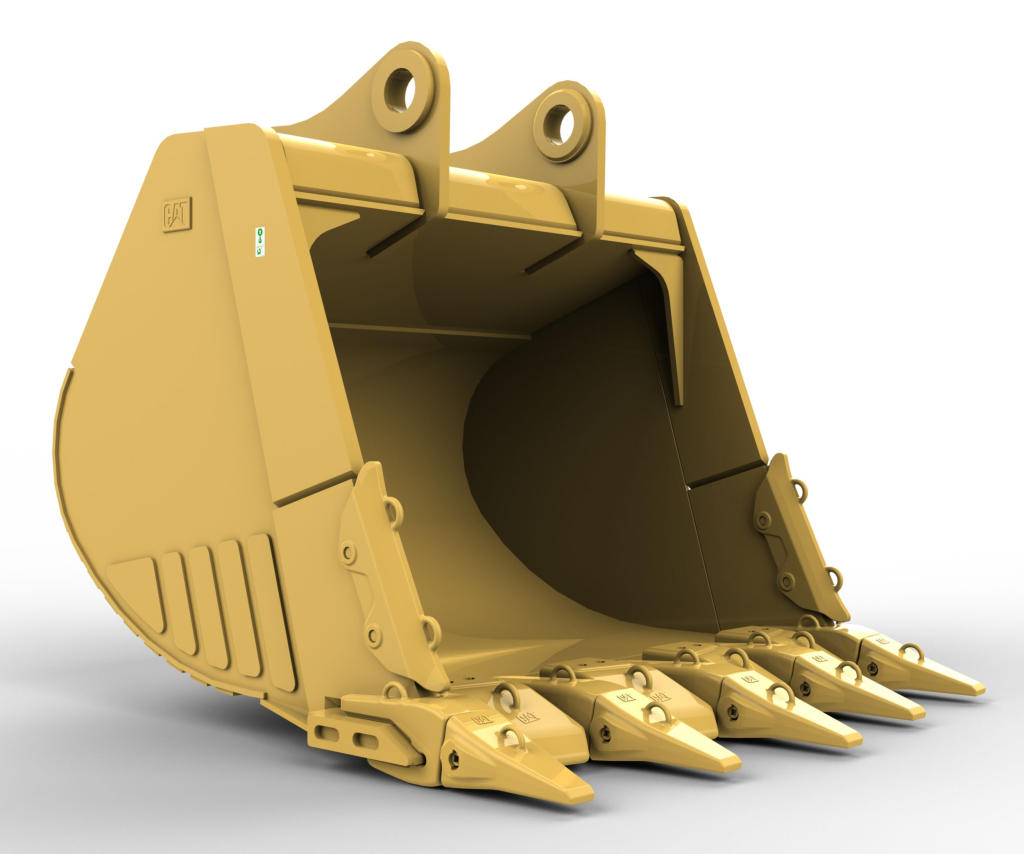

General-Purpose Buckets

General-purpose buckets are the most versatile type of bucket and can be used for a variety of tasks, from digging and loading material to grading and levelling. They come in a range of sizes to suit different excavators, and can be fitted with teeth or cutting edges for extra durability.

If you’re looking for an all-purpose bucket that can handle anything you throw at it, a general-purpose bucket is the way to go.

- Clean-Up BucketsClean-Up Bucket The JIANGTU excavator clean-up bucket is also called the Ditch Cleaning bucket. It has no teeth and has a larger width. The cleaning up bucket is very suitable…Read More

Heavy-Duty Buckets

Heavy-duty excavator buckets are designed for tougher applications and are built to withstand the rigors of digging in challenging materials. Common features of heavy-duty buckets include thicker walls, reinforced teeth and cutting edges, and additional reinforcement around high-stress areas. When selecting a heavy-duty bucket for your excavator, it’s important to consider the type of material you’ll be digging in as well as the weight and size of your machine.

Rock Buckets

There are many different types of excavator buckets, each designed for a specific purpose. Rock buckets are one of the most common types of excavator buckets. They are used for digging in rocky or hard to reach places. The teeth on a rock bucket are very sharp and help to break up the rocks. Rock buckets can be used for both digging and loading rocks onto a truck.

V-Shaped Buckets

V-Shaped Buckets are great for excavating in tight spaces. The V shape allows the bucket to get a good grip on material, while the pointed tip helps penetrate hard ground.

Skeleton Buckets

Skeleton buckets are a versatile attachment for excavators. They can be used for digging, trenching, and even material handling. While they are most commonly used for excavating, skeleton buckets can also be used for other applications such as trenching and material handling.

There are many different types of skeleton buckets available on the market, each designed for a specific application. For example, there are digging skeleton buckets which are ideal for excavating in tough conditions; while there are also utility skeleton buckets which offer a wide range of functions including digging, trenching and material handling.

When it comes to choosing the right skeleton bucket for your needs, it is important to consider the type of work you will be doing with it. If you only need a basic bucket for light duty work, then a utility skeleton bucket may be all you need. However, if you require a more heavy-duty bucket for tougher excavating conditions, then a digging skeleton bucket would be better suited to your needs.

Once you have considered the type of work you will be doing with your skeleton bucket and chosen the right one for your needs, it is important to ensure that it is properly attached to your excavator. This is essential to ensure that your bucket works correctly and doesn’t come loose during use.

Additional Excavator Bucket Types

Some of you may be wondering just how many kind of excavator bucket types are there? Therefore, I’m going to help you clear up that confusion.

People may wander how many kind of excavator bucket types are there?

There are many different types of excavator buckets, each with its own unique purpose and application. Here is a list of some of the most common types of excavator buckets:

Skeleton or teeth bucket: These are the most common type of excavator bucket. They are used for digging and scooping up material, and can be outfitted with different types of teeth depending on the material being dug up.

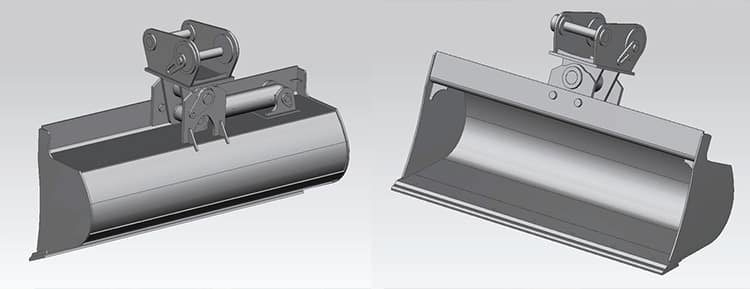

Trenching bucket: As the name suggests, these buckets are designed for digging trenches. They have a narrow profile and curved bottom, which helps them cut through compacted soil more easily.

Ditching buckets: Similar to trenching buckets, ditching buckets are also designed for digging trenches; however, they have a flatter bottom that helps them move material out of the trench more easily.

Grading bucket: These buckets are usually wider than other types of excavator buckets and have a pointed front edge that helps with grading and levelling soil.

Clearing bucket: These buckets have a large capacity and are often used for clearing away debris or large rocks.

Excavator Bucket Teeth and Cutting Edges

Excavator bucket teeth and cutting edges are the two main types of excavator buckets. Each type has its own specific purpose and is best suited for different types of jobs.

Bucket teeth are the pointed, sharpened metal pieces that protrude from the front of the bucket. They are used to break up and dig into hard materials, such as concrete, rock, or frozen ground. Cutting edges are flat pieces of metal that are attached to the bottom of the bucket. They are used to cut through softer materials, such as dirt, sand, or snow.

Excavator Bucket Attachment Systems

There are two main types of excavator bucket attachment systems: quick coupler systems and pin-on systems. Quick coupler systems are faster and easier to change out, while pin-on system buckets tend to be more durable.

Related question

How many types of excavator buckets are there?

For any excavation project, here are the 11 different types of excavator buckets and their applications in case you’re unsure which one to choose: a bucket for digging: a typical kind of bucket used for digging and material movement in landscape and general building projects.

what is the different between the types of digger buckets and excavator buckets?

In general, there is no significant difference between an excavator bucket and a digger bucket. Both terms refer to the same component used for digging and moving materials. However, in specific contexts, “excavator” may refer to larger machines with a broader range of capabilities, while “digger” may refer to smaller machines used for lighter excavation tasks. The size and capabilities of the machine may influence the size and design of the bucket, but the fundamental function remains the same.

What is the difference between a ditching bucket and a grading bucket?

A grading bucket is ideal for leveling and smoothing out soil because it’s wider without causing an increase in weight. A ditching bucket is better suited for maintaining ditches and in construction because it has a smooth front edge. This bucket type is ideal for soil that’s free of roots or rocks.

How do I choose an excavator bucket?

When choosing an excavator bucket, the first thing to consider is the specific application and type of material you are handling. You typically want to find the biggest bucket for your job, taking into account the material density and the size of the hauler truck.

Why do excavator buckets have teeth?

Although the toothed bucket is mainly used to break up material, it is also the best choice for bulk moving material and removing objects that might be stuck in the ground, like roots or large rocks, as the teeth help with scooping and gripping the material.

How do you calculate excavator bucket capacity?

First, determine the bucket length (in). Next, determine the bucket width (in). Next, determine the bucket height (in). Finally, gather the formula from above = LBC = L/12 * W/12 * H/12.