The Ultimate Guide To Jobsite Safety | Demolition Attachments

Keywords: demolition attachments, demolition attachments for excavators

Keeping your workers healthy and productive is essential to ensuring the success of your company and your projects. Doing this starts with implementing processes and procedures for safety on the jobsite and then making certain everyone knows them and adheres to them. Reminding even long-time workers of these rules can help reduce injuries and accidents.

Contact us at Louisiana Cat for genuine Cat® products and information on how to safely use them and improve where you work.

THE IMPORTANCE OF SAFETY TRAINING

According to the Occupational Safety and Health Administration, OSHA, the construction industry has a higher rate of fatal injuries than other sectors. OSHA sets forth the requirements for workplace safety, but it is up to you to ensure you follow their regulations.

Safety training can save the lives of your workers as well as the productivity of your company. With this guide to safety on the construction site, you will know exactly what you need to do to prevent accidents in different weather conditions and around various equipment.

SAFE EQUIPMENT OPERATION

By teaching safe equipment operation, you could help prevent one of the 100 annual deaths or 95,000 annual injuries from industrial vehicle operation. Several things make equipment safer to use:

- Training: Thoroughly train workers on how to run equipment correctly. Do not allow workers to use any machinery they are not qualified to operate.

- Safe Driving: Create a jobsite speed limit of five miles per hour.

- Attachments: Do not use accessories that are not designed for the equipment.

- Maintenance: Conduct regular maintenance on the equipment. This includes procedures such as ensuring engine fluid levels are where they should be and inspecting the brakes. Check the tires as well for proper tread depth, inflation and condition.

- Load Limits: Know the load limits of your equipment. Never carry more than the maximum amount.

- Safety Parts: Check that all safety systems on the equipment work, including reverse alarms, the rollover structure, and seatbelts.

- Load Carrying: Never allow workers to lift loads with a crane or lift truck over or near others.

- Clear the Area: Keeping people away from an industrial machine is essential. You also need to keep the equipment away from active power lines. Allow at least 10 feet of clearance between the device and the nearest power lines.

- Operator Position: For anyone using a machine, never allow the person to stand on the equipment where there is not a footrest. Climbing on equipment for any reason poses a severe hazard. Also, remind drivers to safely enter and leave the vehicle and use a seatbelt when the vehicle is moving.

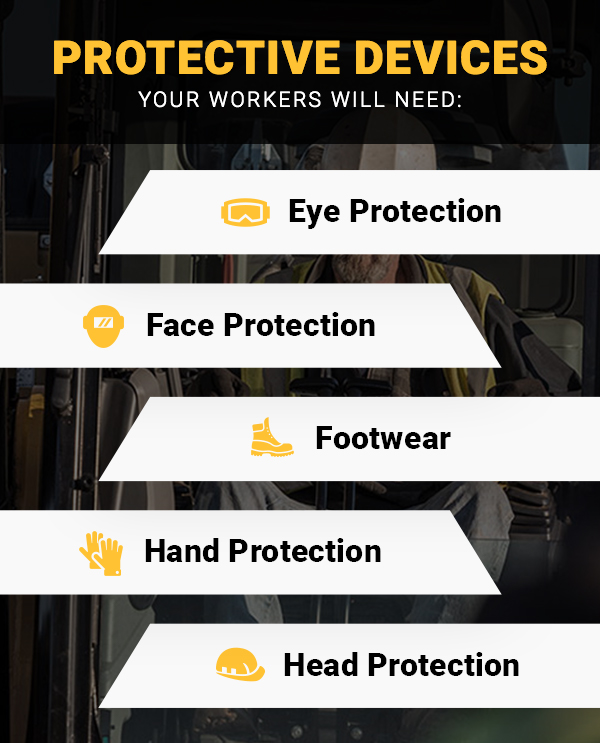

PERSONAL PROTECTIVE EQUIPMENT

Depending on what you’re doing on your jobsite, the level of personal protection will vary. For instance, you may not need a respirator if the job does not deal with chemicals. However, all construction safety tips you see will remind everyone on site to wear hard hats. In fact, in 2004, not having head protection on a construction site was one of the 10 most common violations OSHA found. Without head protection, you could die from something as simple as a falling tool. If you wore a hard hat, though, the same incident would likely only give you a headache.

As important as personal protective equipment, or PPE, is to use, many workers don’t wear it. In a survey of workers, 14 percent responded that their bosses did not tell them they were required to wear PPE. The same poll found 25 percent of workers did not get any PPE training. These results show companies need to do more to help their workers learn about PPE. Here are the protective devices you need to keep available for your workers:

- Eye Protection: Goggles keep foreign matter out of the eyes when working with chemicals. Nailing, cutting, grinding and welding also need eye protection.

- Face Protection: For welding, grinding and working with electricity, face and eye protection keep sparks from burning the face.

- Footwear: On a construction site, everyone needs to wear steel-toed shoes to prevent crushed toes. Additionally, the soles should be non-skid and resist punctures from nails or other sharp objects on site.

- Hand Protection: Like eyewear, have several types of gloves available for the many jobs around your worksite. Sleeved, insulated gloves protect the skin when working with electricity. Welding gloves keep the hands safe when welding. Rubber gloves are ideal for concrete work.

- Head Protection: Keep hard hats in good condition. Check them regularly for signs of damage. Throw away any hard hats with cracks or dents in them.

Always train workers before they start about the types of PPE available and when to use them. Enforce the use of PPE on the construction site to prevent serious injuries. Discomfort is not an excuse to skip wearing proper PPE. Using protective equipment could save a worker from death or severe injury.

SAFETY IN HOT WEATHER

In Louisiana, construction workers know how hot it can get during the summer. Part of the problem comes from the extra humidity, which makes the heat worse. Working in hot conditions can be dangerous, and even physically fit construction workers can experience heat illness.

TYPES OF HEAT ILLNESS

Heat illnesses your workers can experience include:

- Heat Fatigue: Those not used to operations in hot weather often feel tired and less capable of working at their average rate. This condition is known as heat fatigue. Cool off workers experiencing this condition to prevent symptoms and problems from worsening.

- Heat Rash: When someone sweats, and the sweat stays on the skin, it could cause heat rash. Sweat often does not evaporate in humid conditions or under non-breathable clothing. Both heat and bulky PPE can contribute to heat rash, and the rash can get infected if the person does not treat it. Wiping off sweat regularly and taking breaks can prevent rash development.

- Heat Cramps: An imbalance of minerals in the body from too much sweating can lead to muscle cramps. Workers who don’t drink enough when working in hot conditions can get cramps. Consuming sports beverages with electrolytes and carbohydrates can help prevent heat cramps.

- Heat Exhaustion: While heat rash and cramps only affect parts of the body, heat exhaustion takes a toll on the whole body. Workers with heat exhaustion will feel dizzy, nauseous and weak. These symptoms become especially dangerous when working with heavy equipment or in high places. Without treatment, the worker could collapse from the heat. Get the person out of the weather and encourage them to drink plenty of fluids. This type of heat stress responds well to prompt treatment, but without care, it can become heat stroke.

- Heat Stroke: The body temperature in someone with heat stroke soars to over 105 degrees. To identify heat stroke, look at the skin. The victim’s skin becomes hot and dry, as opposed to someone with heat exhaustion that continues to sweat profusely. This condition can be fatal if it’s not addressed. Call for emergency medical care and move the worker to a cool place. Expose as much skin as possible, wet it with cool clothes and allow plenty of air flow to help the victim cool off until emergency medical personnel arrive.

PREVENT HEAT ILLNESS ON THE JOBSITE

As an employer, you can do multiple things to help prevent heat illness on your construction site. Use this guide to jobsite safety to keep your workers safe in hot weather:

- Train Workers: Teach workers to recognize signs of heat stress in themselves and others.

- Encourage Breaks: Especially for workers who have not gotten used to working in the heat, give plenty of breaks to allow your employees to drink water and get out of the weather. Give workers more breaks if they must wear bulky PPE, if the temperature or humidity has increased recently, if they work in areas without air flow or if they do physically demanding work.

- Provide Drinks: Have plenty of cold water available and ensure it has a temperature below 59 degrees Fahrenheit. You can also keep sports drinks on hand for your workers. Discourage them from drinking carbonated beverages or alcohol even off the job to prevent heat illnesses.

- Acclimate Workers: A sudden heat wave may drop your jobsite productivity temporarily until your workers get used to the heat. Give workers one to two weeks to become accustomed to working in the heat. Increase new workers’ efforts 20 percent daily. For existing workers, cut the workload in half the first day of high temperatures and increase it by 10 percent more each day.

SAFETY IN COLD CONDITIONS

Wintry weather can be just as dangerous as hot weather. For some workers who have medical conditions or are unfit, the cold poses a more serious hazard. Though temperatures in the South rarely reach subzero levels, cold temperatures can still put people outside at risk of frostbite, trench foot, and hypothermia:

- Frostbite: Skin exposed to water, wind, and cold could freeze. Left untreated, the tissues under the skin can freeze, too. Some people need amputations of body parts affected by frostbite. Keeping covered and dry can prevent this condition.

- Trench Foot: Trench foot, also called immersion foot, happens even in warm temperatures up to 60 degrees Fahrenheit with feet that stay constantly wet. The cold, wet feet lose heat 25 times faster than dry feet and can result in foot injuries. Keeping the feet dry by changing wet socks periodically throughout the day can prevent this condition.

- Hypothermia: Though the most severe cold illness, hypothermia can occur even at temperatures higher than 40 degrees Fahrenheit if a person is wet. Hypothermia occurs when the body’s temperature drops from its normal 98.6 degrees to less than 95 degrees. Without help, hypothermia can be fatal. Recovering from the cold in a warm, dry area, especially on windy or wet days can prevent the condition.

PREVENT COLD STRESS AT WORK

Just as you can help workers stay healthy in hot weather, you can do the same in freezing conditions with this chilly weather jobsite safety guide:

- Training: Teach your workers about preventing, recognizing and treating trench foot, frostbite, and hypothermia.

- Provide Ways to Get Warm: Have a warm place available for workers to get a break from the cold. Radiant heaters outside and sheltered areas protect your workers from cold, windy conditions. Also, supply warm, sweetened, non-alcoholic, non-caffeinated beverages for your workers to prevent dehydration.

- Offer Cold-Weather PPE: The PPE your employees wear when temperatures drop should include insulated, waterproof materials. Teach workers the importance of dressing in layers that pull sweat away from the body and prevent rain from seeping through their clothes to the skin. Encourage workers to wear head coverings and ski masks in extra chilly weather to protect the head and face from freezing.

SAFETY BENEFITS OF CAT® EQUIPMENT

Cat machines have many features to increase the safety of those using them and those around the area. Monitoring equipment on Cat vehicles helps you see whether your workers are using the machines safely. You can choose Cat Link or Cat Detect to boost the safety of your construction vehicles:

- Cat Detect: The Cat Detect system includes multiple options including CCTV and RFID to monitor construction vehicles. Security systems prevent theft, and object detection systems help warn the driver of hazards nearby. You can install this system on new or used machines for a safer, more secure construction site.

- Cat Link: Part of creating a construction site safety guide means collecting data about how your employees need to improve on the jobsite. To use this system, add the Product Link hardware to your machinery and connect it to the VisionLink interface, a web-based software. The type of subscription you have determines the type of information collected. You could get immediate alerts about vehicle use, fault codes and other errors, no matter where you are. No other company besides Caterpillar® has Cat Link technology.

You know the Caterpillar brand for its bright yellow vehicles and long-standing reputation. Safety at work continues to be an essential part of the Caterpillar name, which explains why the company continues to develop leading technology to make construction sites safer and more secure.

BENEFITS OF LOUISIANA CAT FOR SAFETY

To start improving the safety of your construction site, begin by buying the Cat vehicles you know and trust from us at Louisiana Cat. One of the ways we help our customers stay safe is by offering jobsite safety tips through training courses. These courses are a part of our mission to exceed our customer’s expectations and to create mutually beneficial partnerships. We want to keep our customers safe while offering them the Cat vehicles they need to be productive on the jobsite.

DISCOVER HOW LOUISIANA CAT STANDS APART

At Louisiana Cat, we’ve been in business for more than 80 years, offering our customers safety instruction and quality equipment to improve their jobsite. When you work with us, you’ll see how we stand apart from other construction vehicle dealers. You’ll experience our values of honesty, responsibility, commitment, team orientation, loyalty, humility, trustworthiness and self-motivation.