Installation Guide and Instructions for Excavator Quick Hitch

How to install the pipeline of excavator quick hitch and attention points during the processing are shared as below. It is simple. If you are interested, welcome to check.

Installation

Pipeline installation steps

First weld the iron pipe to the forearm with the pedestal.

Weld the 90°butt joint above the iron pipe to connect the pipe②

Weld the 90°butt joint to connect pipe ① and well adjust the angle

| Level | Distance(mm) |

| 02 | 150 |

| 04 | 150 |

| 06 | 200 |

| 08 | 230 |

| 10 | 280 |

| 17 | 280 |

The distance between the bottom of iron pipe and theforearm.

The 90°butt joint must be tightly topped to the iron pipe. Tighten the pedestal to weld it.

Connect pipe ② to pipe③

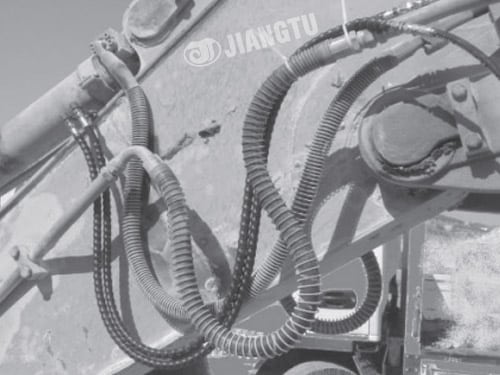

Connect the pipe ③ and pipe ④ with the double nipple and tighten the boom with the cable tie.

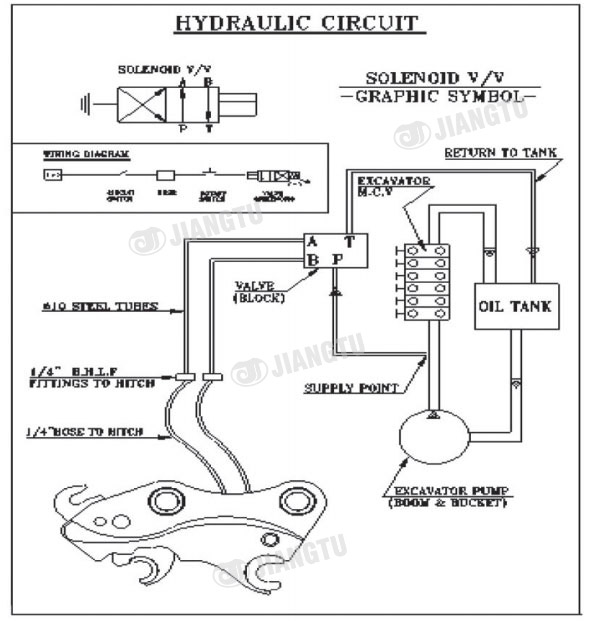

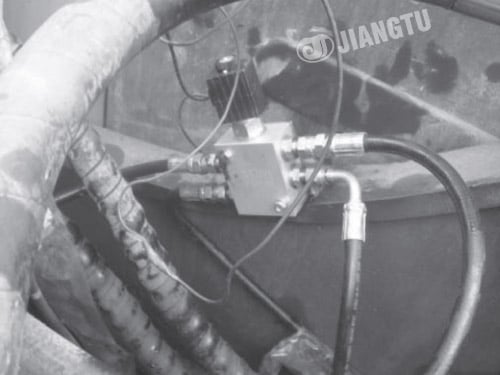

Connect Pipe④ to nexus A and B of the solenoid value. The solenoid value is stabilized or welded to the bottom of the boom.Two wires of the solenoid value (one connects the solenoid value, another connects the standby wire of mains and is pulled to the cab being connected to the switch.)

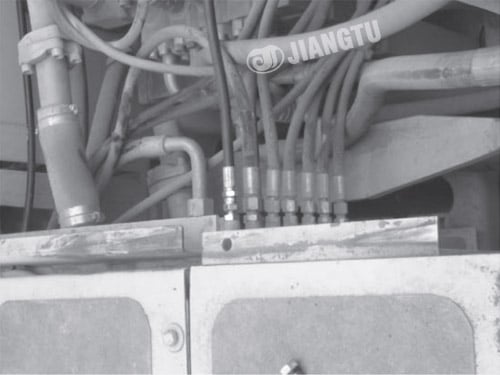

Connect Pipe⑤ to the nexus P, T of the solenoid value P(oil in) will get pilot oil.

Remarks: When the switch is off power and there is oil in the nexus P, nexus A will feeds oil.

Connect Pipe⑤ to the nexus P,T of the solenoid value, the nexus T (oil return) is connected to the hydraulic tank or the return pipeline.

Switch connection: (1) Green wire connects the solenoid valve. (2) Red wire connects the positive pole. (3) Black wire connects the negative pole.

When switch on (turn right), the buzzer alarms and the cylinder retracts; when switch off (turn left), the cylinder extends.

Remarks: When the switch (turn left) is off, the cylinder is in a state of oil feeding, it will always top the pin.

The switch is drilled to be stabilized on the spare switch position.

When change the attachments, switch on (turn right), the forearm cylinder will retract and the fixed hook will be stuck.

When the fixed hook is stuck, slowly extend the forearm cylinder, and the coupler will be put down. Then switch off (turn left), the safety pin will be plugged into the identifying hole to lock it according to the instruction.

JIANGTU Attachments, as a breaker manufacturer for 12 years. We could provide various types of hydraulic hammer breakers and the chisel selection recommendation and installation instructions for you. If you have any questions, please feel free to contact us.

Read More: Excavator Attachments Select Guide

Hydraulic Breaker/Hammer Select Guide

Hydraulic Hammer/Breaker and Chisel Tools Guide

Hydraulic Grapple Select Guide

Earth Auger Select Guide

JIANGTU Excavator quick couplers, also named as a quick hitch, bucket pin grabber, quick connector, can quickly connect various attachments (bucket, hydraulic breaker, plate compactor, log grapple, ripper, etc.) on excavators, which can expand the scope of use of excavators and can save time and improve working efficiency.

We can offer the OEM/ODM services of excavators attachments. The product can be customized according to your personalized requirements. Please offer your design documents or tell us your ideas and our R&D team will do the rest.