How Mini Excavator Breakers Are Revolutionizing Construction Projects?

Keywords: hydraulic breakers for mini excavators, hydraulic breakers for excavators

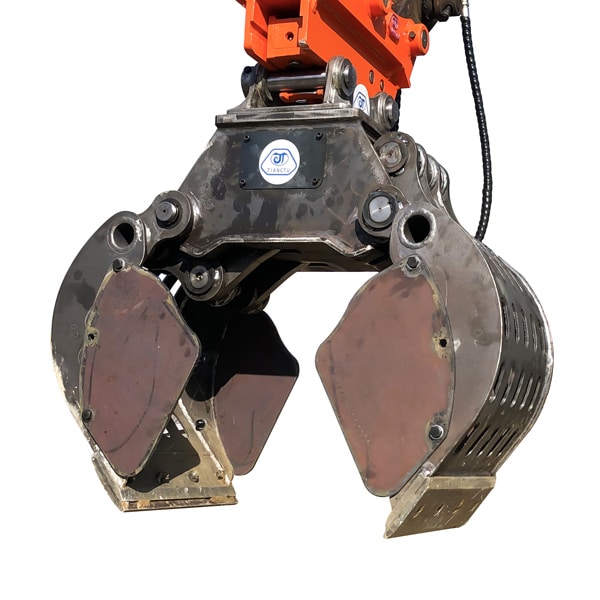

Mini excavator breakers, or hydraulic breakers or hammers, are attachments used with a mini excavator to break up concrete, rock, and other hard materials. The mini excavator breakers use hydraulic power to apply pressure and force to the broken material. It is attached to the end of the excavator’s arm or boom and can be operated using controls from the excavator’s cab.

Mini excavator breakers come in different sizes and shapes and are used for various applications, such as demolition, quarrying, landscaping, and construction. They are often used in tight spaces where larger machinery cannot access them, making them a popular choice for small-scale projects.

When selecting mini excavator breakers, it is important to choose the right size and weight for your excavator and consider the material you will be breaking and the frequency of use. Following all safety guidelines and manufacturer recommendations for using and maintaining the attachment.

Choosing The Right mini Excavator Breakers Hammer

When choosing the right excavator breakers hammer, several factors must be considered to ensure you get the best one for your needs.

Size and Compatibility:

It would be best if you kept in mind that the breaker is compatible with the size and weight of your excavator. You will need to know the weight and size of your excavator to select a breaker that matches its operating capacity.

Application:

Consider the type of work you will do with the breaker. Different breakers are designed for different applications, such as breaking concrete, rocks, or asphalt. Choose a breaker that is suited to your specific job requirements.

Power and Impact:

Choose a breaker with the right power and impact force for the job. It will depend on the hardness and density of the material you will break. A breaker with too little power will struggle to break hard materials, while one with too much power may cause unnecessary damage.

Maintenance and Support:

Consider the maintenance requirements of the breaker and ensure that you have access to parts and support when needed. Choose a breaker that is easy to maintain and comes with a warranty.

Type of Concrete:

The type of concrete you will break determines the tool you need. For example, if you want to break up reinforced concrete, you will need a tool to penetrate and cut through steel rebar.

Excavator Size:

Ensure that your concrete breaker tool matches your excavator’s size and weight. You will need to know the weight and size of your excavator to select a breaker tool that matches its operating capacity.

Size of the Concrete:

The size of the concrete also determines the type of tool you need. A large concrete slab will require a more powerful tool than a small concrete wall.

Power and Impact:

Choose a concrete breaker with the right power and impact force. It will depend on the hardness and density of the concrete you will break. A tool with too little power will struggle to break hard concrete, while one with too much power may cause unnecessary damage.

Price:

At last, consider the breaker’s price and compare it to similar models to ensure you get a good value for your money. While price is important, it should not be the only factor you consider when choosing a breaker.

Types of Choosing mini Excavator Breakers

Several mini excavator breakers are designed for different applications and working conditions.

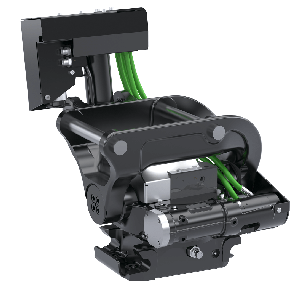

Side-Mounted Breakers: Side-mounted breakers are attached to the excavator’s boom and are often used to break up concrete, asphalt, and other hard materials. They are particularly useful in confined spaces where a top-mounted breaker would not fit.

Top-Mounted Breakers: Top-mounted breakers are attached to the excavator’s boom and are ideal for breaking up larger rocks and boulders. They are used in quarrying and mining applications.

Box-Type Breakers: Box-type breakers are designed for breaking up concrete and other hard materials. They are mounted on the front of the excavator and are available in different sizes depending on the size of the excavator.

Silenced Breakers: Silenced breakers come to reduce noise levels and are often used in urban areas where noise pollution is a concern. They are used for breaking up concrete and asphalt.

Hydraulic Breakers: Hydraulic breakers use hydraulic fluid to generate high-pressure and high-velocity impacts, making them ideal for breaking up tough materials such as rock, concrete, and asphalt.

Pneumatic Breakers: Pneumatic breakers use compressed air to generate the force required to break up materials. They are best for working in areas with very low noise levels.

How to operate mini excavator breaker safely

Operating a mini excavator breaker safely is important to protect yourself, others around you, and the equipment itself.

Read the Operator’s Manual: Familiarize yourself with the operator’s manual before operating the breaker. Understand the safety guidelines and recommended operating procedures to prevent accidents.

Wear Protective Equipment:

Wear appropriate personal protective equipment (PPE), including eye protection, hearing protection, a hard hat, gloves, and safety boots. PPE helps protect you from flying debris, noise, and other hazards.

Inspect the Equipment:

Inspect the mini excavator breaker before each use. Check for any signs of damage, cracks, or leaks. Ensure that all bolts, nuts, and fittings are tight and secure.

Position the Excavator:

Position the excavator on a stable surface and ensure it is level before operating the breaker. Ensure the excavator is not too close to obstacles, structures, or people.

Start Slowly:

Start the breaker slowly to get a feel for how it operates. Gradually increase the speed and force as needed.

Use Proper Techniques:

- Use the proper techniques when operating the breaker.

- Avoid hitting the breaker at an angle, as this can cause it to deflect and create dangerous flying debris.

- Also, avoid using the breaker to pry or lever materials.

Shut Down Safely:

Shut down the mini excavator breaker properly when finished using it. It shuts off the engine, lowering the breaker to the ground and engaging the safety lock.

Following these safety tips, you can safely operate a mini excavator breaker and reduce the risk of accidents or injuries.

Conclusion

Mini excavator breakers are essential for breaking up concrete, rocks, asphalt, and other hard materials in construction and demolition projects. Choosing the right mini excavator breaker is critical to ensuring the safety and efficiency of your work. It is also important to operate the mini excavator breaker safely and follow the manufacturer’s guidelines, and you can contact us for more details.